The Impact of Laser Marking and Cutting Technology on Wooden Materials

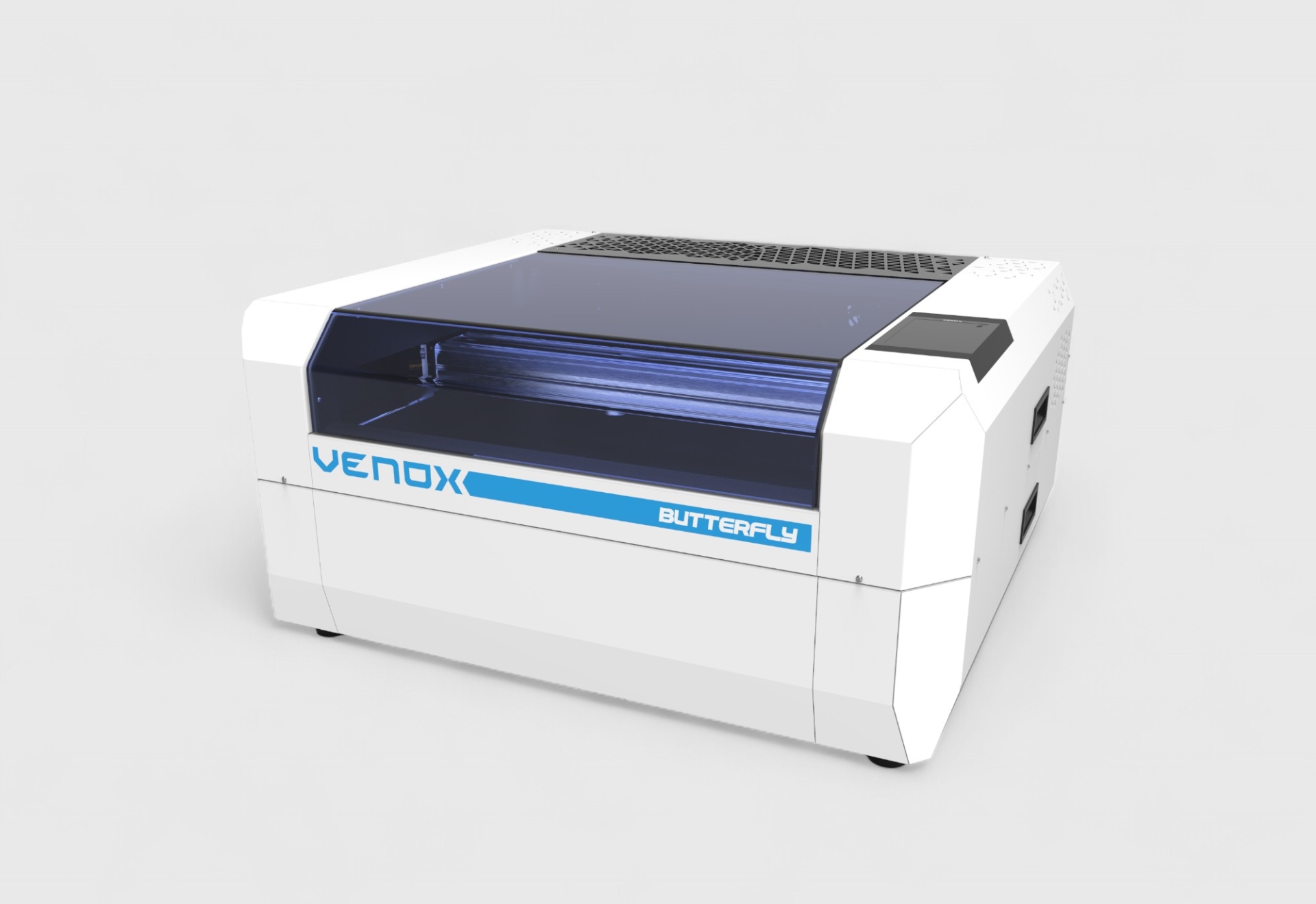

Wood is a popular material used in various fields such as decoration, furniture, packaging, art, advertising, and crafts due to its natural and aesthetic appearance. Laser marking and cutting technology enable the creation of detailed patterns, text, logos, and custom designs on wooden surfaces with high precision. Compared to traditional methods, lasers offer a contactless, fast, and flexible production process, providing significant advantages in the woodworking industry.

The Effect of Laser Marking on Wood

Laser marking works by either changing the color of the wood with heat or burning a specific layer of the surface, creating permanent markings. This results in aesthetic, legible, and detailed designs.

Advantages of Laser Marking on Wood

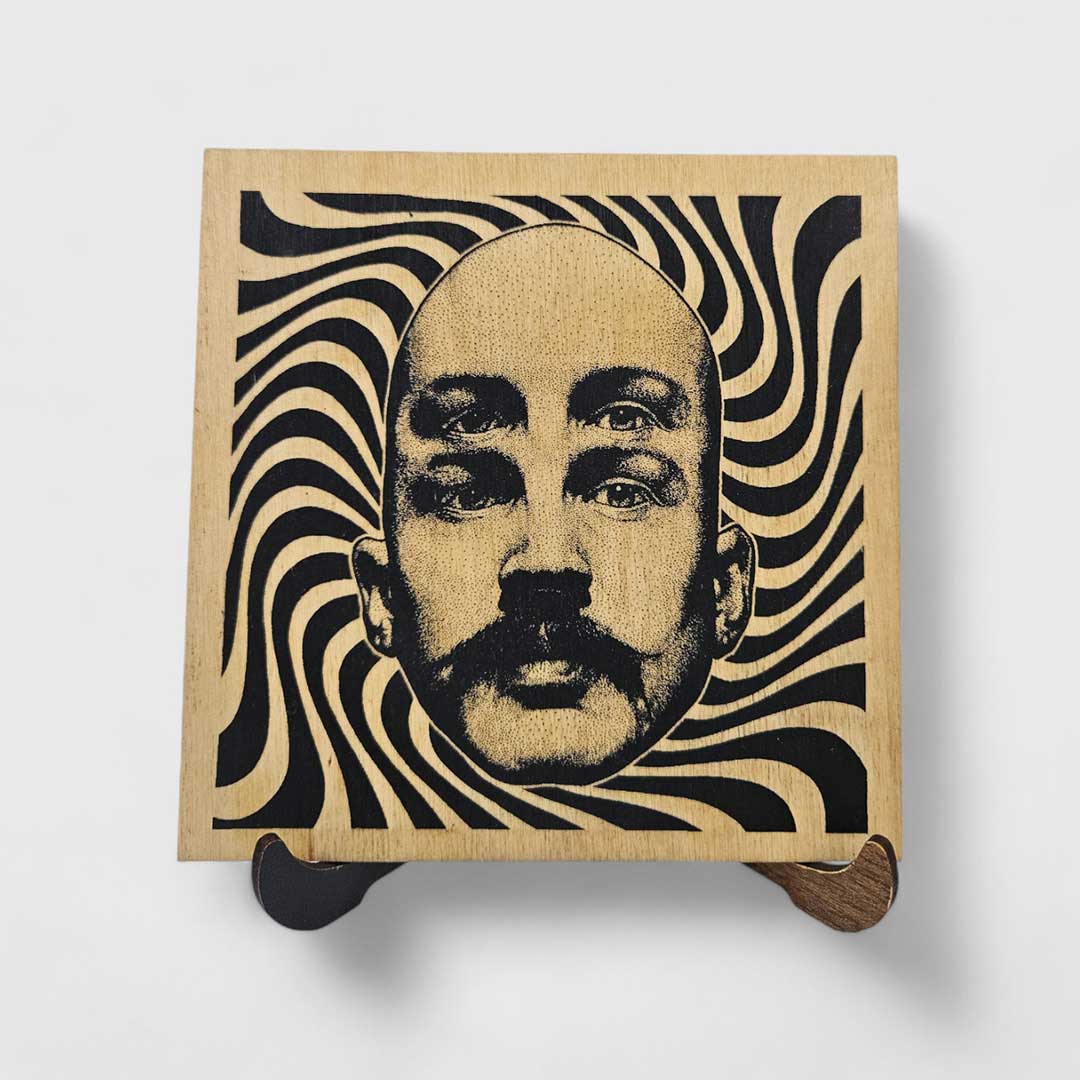

- High Contrast and Durability: Laser marking creates high-contrast markings without damaging the natural wood texture. The markings are fade-resistant and wear-resistant, ensuring long-lasting results.

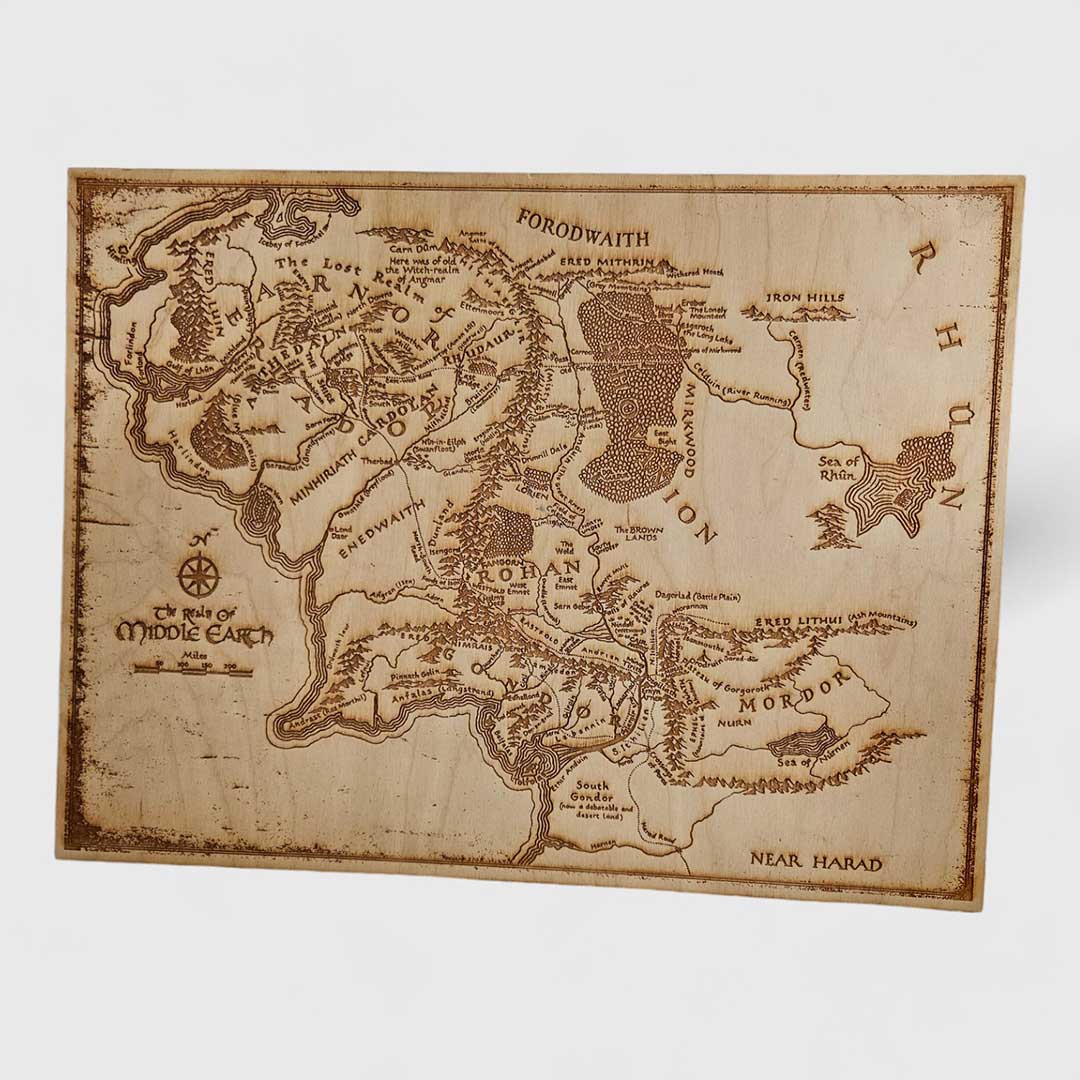

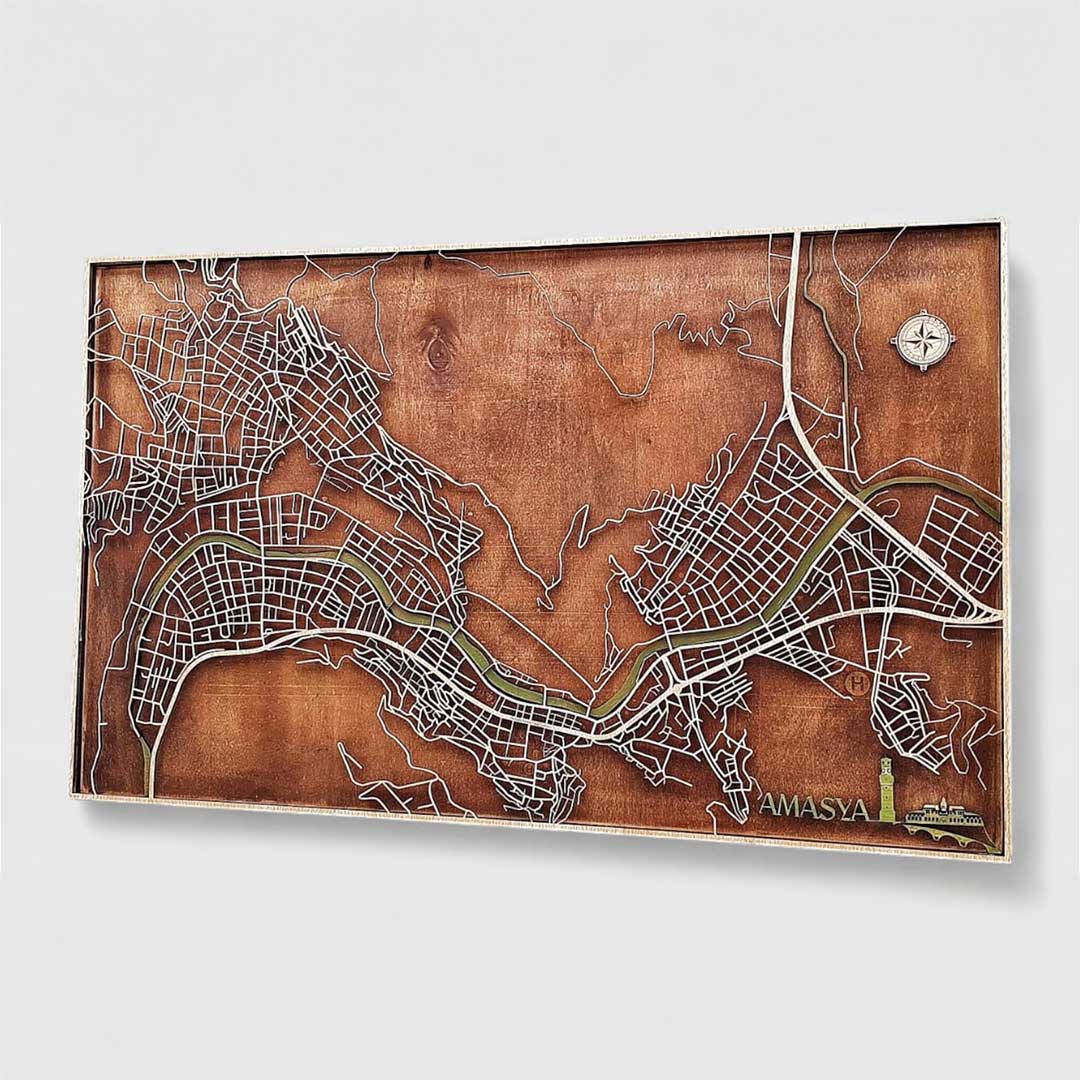

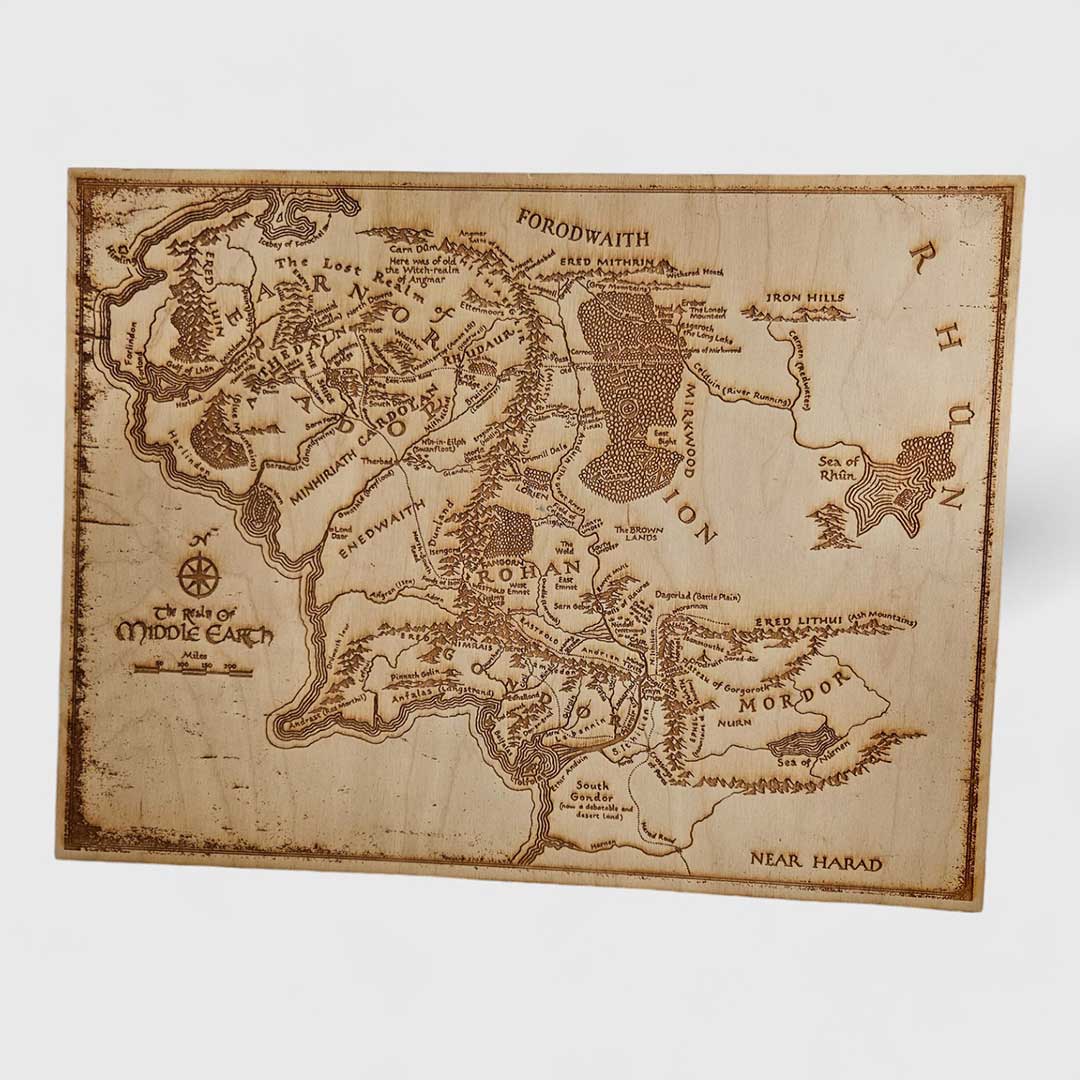

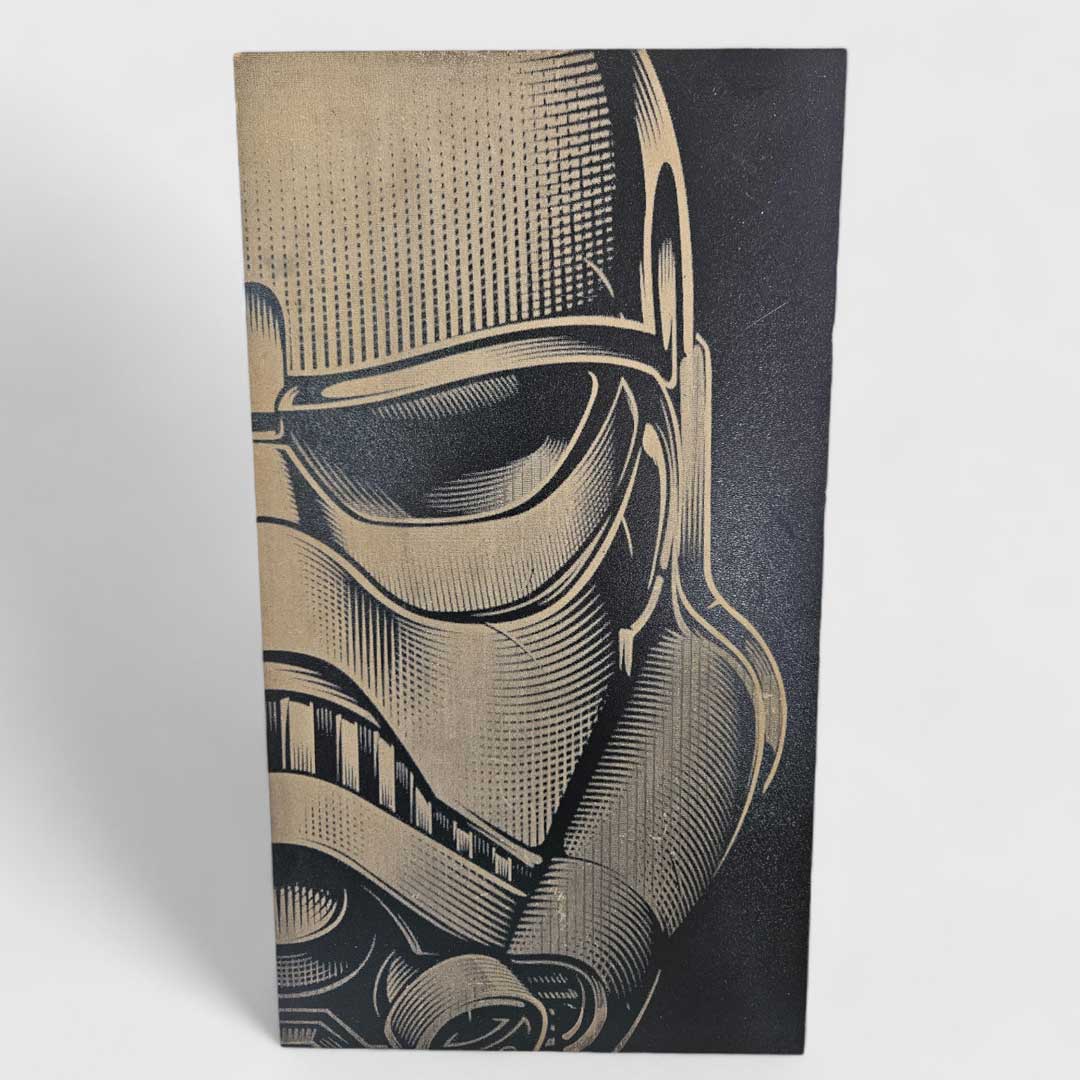

- Precision and Fine Details: Laser technology allows for high-resolution engraving, enabling the creation of complex patterns and artworks, even with the smallest details.

- Compatibility with Various Wood Types: It works efficiently with different types of wood such as MDF, plywood, oak, beech, walnut, spruce, and pine, regardless of their hardness or density.

- No Chemicals or Ink Required: Unlike traditional printing and marking methods, laser marking offers a clean, eco-friendly process without the use of inks or chemicals.

- Artistic and Decorative Applications: Laser marking on wood is ideal for creating custom gifts, promotional products, furniture details, signage, and artworks.

Laser marking offers both practicality and aesthetic value, making it an essential tool for various industries working with wood.