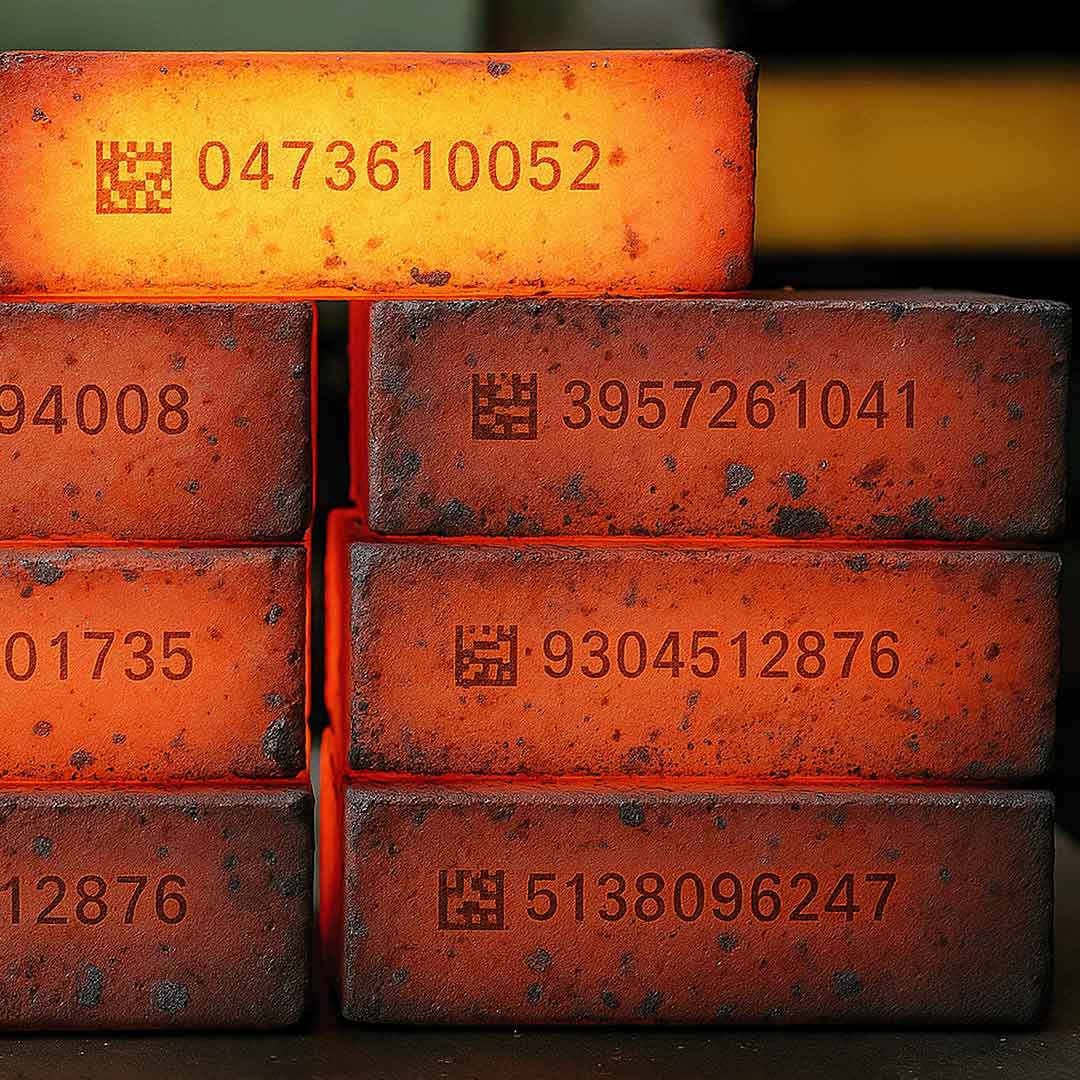

Laser marking is widely used to permanently and legibly engrave serial numbers, production dates, and traceability codes onto metal components. This is especially critical for quality control and full traceability throughout the product lifecycle.

Full Traceability: With serial numbers and tracking codes, each mechanical part can be traced from production to end-of-life.

Durable and Permanent Marking: Laser markings are resistant to abrasion, chemicals, heat, and physical impact.

Improved Production and Inventory Management: Tracking codes can be integrated into automation systems, streamlining inventory and maintenance processes.

High Speed and Precision: Laser marking is fast, contactless, and highly accurate, delivering excellent readability on metal, plastic, ceramic, and composite surfaces.

Compliance with Industrial Standards: Ensures compliance with global regulations in industries such as automotive, aerospace, defense, energy, and medical.

Example Application: On automotive components such as brake discs, chassis parts, or engine components, unique serial numbers and production dates are laser-marked to enable full traceability and simplify maintenance or recall processes.