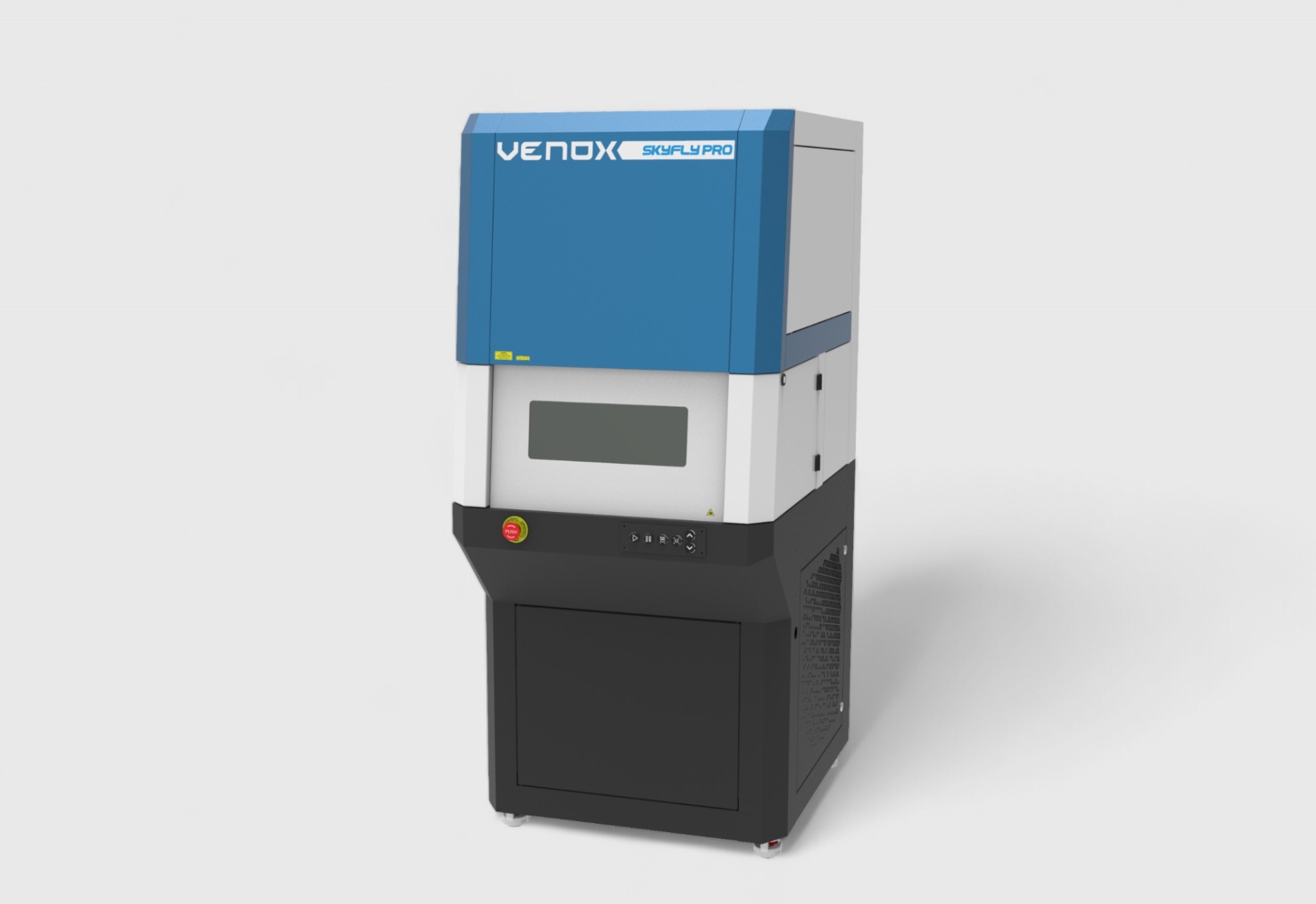

Venox Teknoloji provides reliable solutions for many industries with its laser marking systems developed to strengthen product identification, traceability, and quality processes in industrial manufacturing. Laser marking enables permanent, clear, and repeatable markings on many surfaces such as metal, plastic, glass, and more.

Thanks to its non-contact operating principle, marking can be performed at high speed and with stable quality without creating mechanical stress on the surface. A structure that does not require consumables reduces operating costs while also supporting sustainable manufacturing goals.

Codes and Information That Can Be Marked

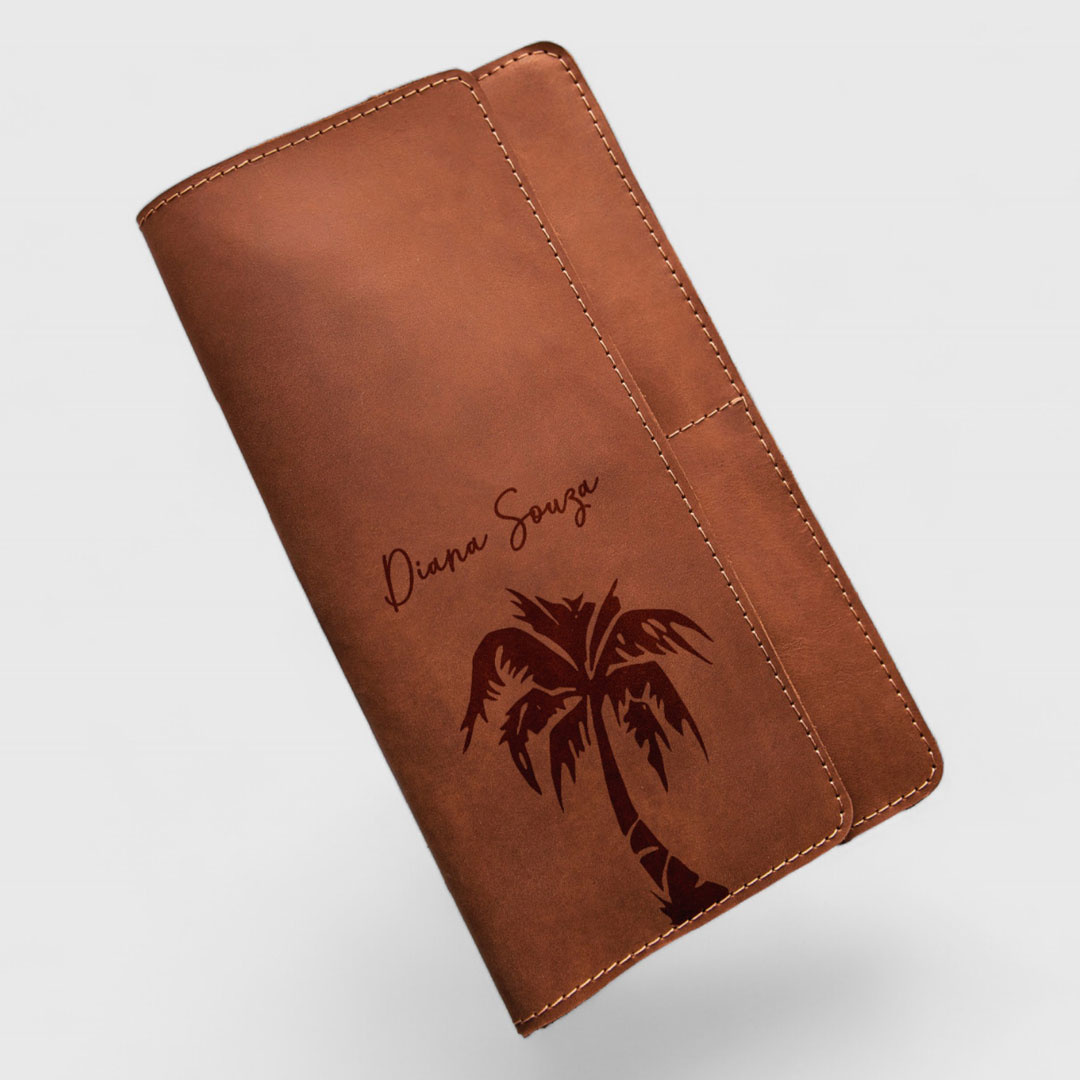

Venox laser marking machines enable fixed and variable information required in production processes to be applied directly onto the product. Laser-created marks are designed to remain legible throughout the product’s lifetime.

Serial number

QR code

DataMatrix code

Barcode

Product and part codes

Production date and lot information

Company logo and brand details

Technical warnings and regulatory markings

Applications and Industries

Venox laser marking solutions are used with confidence in many industries with different production volumes and automation levels.

Automotive

White goods

Electronics and electrical equipment

Medical products and devices

Packaging and food

Energy and defense industry

Metalworking and machine manufacturing

Suitable Materials

Thanks to a wide range of laser source options, Venox systems adapt to different surface types and deliver high-contrast, clear markings.

Metals and metal alloys

Plastics and polymer-based materials

Glass surfaces

Ceramics and coated parts

Composite materials