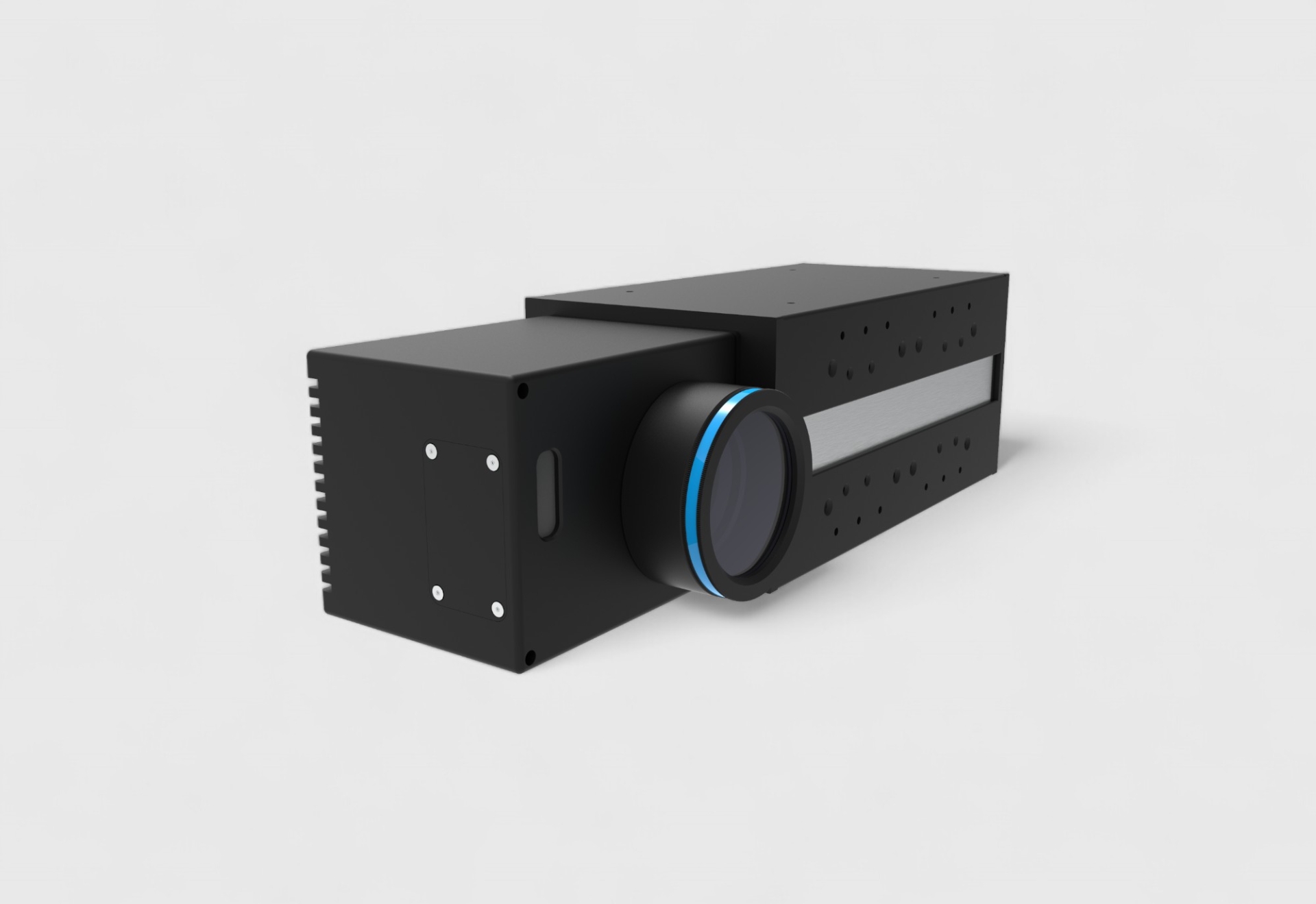

Venox Teknoloji's fiber laser marking systems make a difference in production processes with high performance and reliability. They are capable of producing clear, permanent, and repeatable markings, especially on metal and plastic surfaces. High-speed marking, long-term uninterrupted operation, and low maintenance requirements make these systems ideal for industries such as automotive, electronics, and medical. Thanks to advanced software integrations and user-friendly interfaces, they can be easily integrated into different production lines. Venox fiber laser solutions are optimized with a focus on energy efficiency to support sustainable production goals.

Venox Teknoloji's fiber laser marking systems enhance processing quality with solutions that can be configured to meet specific industrial needs. Operating with high precision on metal and plastic, these systems are widely preferred in areas such as automotive, electronics, medical, and jewelry. With their energy-efficient design, they contribute to sustainable manufacturing, while also serving as a strong alternative for coding and product identification applications in the food and packaging sectors. With an advanced software infrastructure and practical user features, they adapt quickly to your production environment.

What is a fiber laser and how does it work?

Fiber lasers are laser systems in which light is amplified and concentrated within a fiber-optic structure and directed to the surface with high accuracy. This design provides high energy stability during marking and clarity in fine details.

Which materials can be marked with a fiber laser?

Fiber laser marking can deliver effective results not only on metals such as steel, stainless steel, and aluminum, but also on plastics, ceramics, and composite materials.

How is the maintenance of fiber laser systems performed?

Fiber laser systems require low maintenance. Regular cleaning of the lens/protective window and periodic software checks are sufficient to keep performance stable over a long period.

Is fiber laser marking permanent?

Yes, fiber laser marking is permanent. When processed with the right parameters, it creates wear-resistant, long-lasting marks on the surface.

What is the cost of fiber laser systems?

System cost varies depending on laser power, working area, automation options, and software modules. Although the initial investment may appear high, it provides long-term advantages thanks to low operating expenses.

What are the safety precautions for fiber lasers?

For safe operation, precautions such as a protective enclosure, appropriate laser safety eyewear, an emergency stop system, and operator training are implemented. This ensures safe and controlled operation in the production environment.