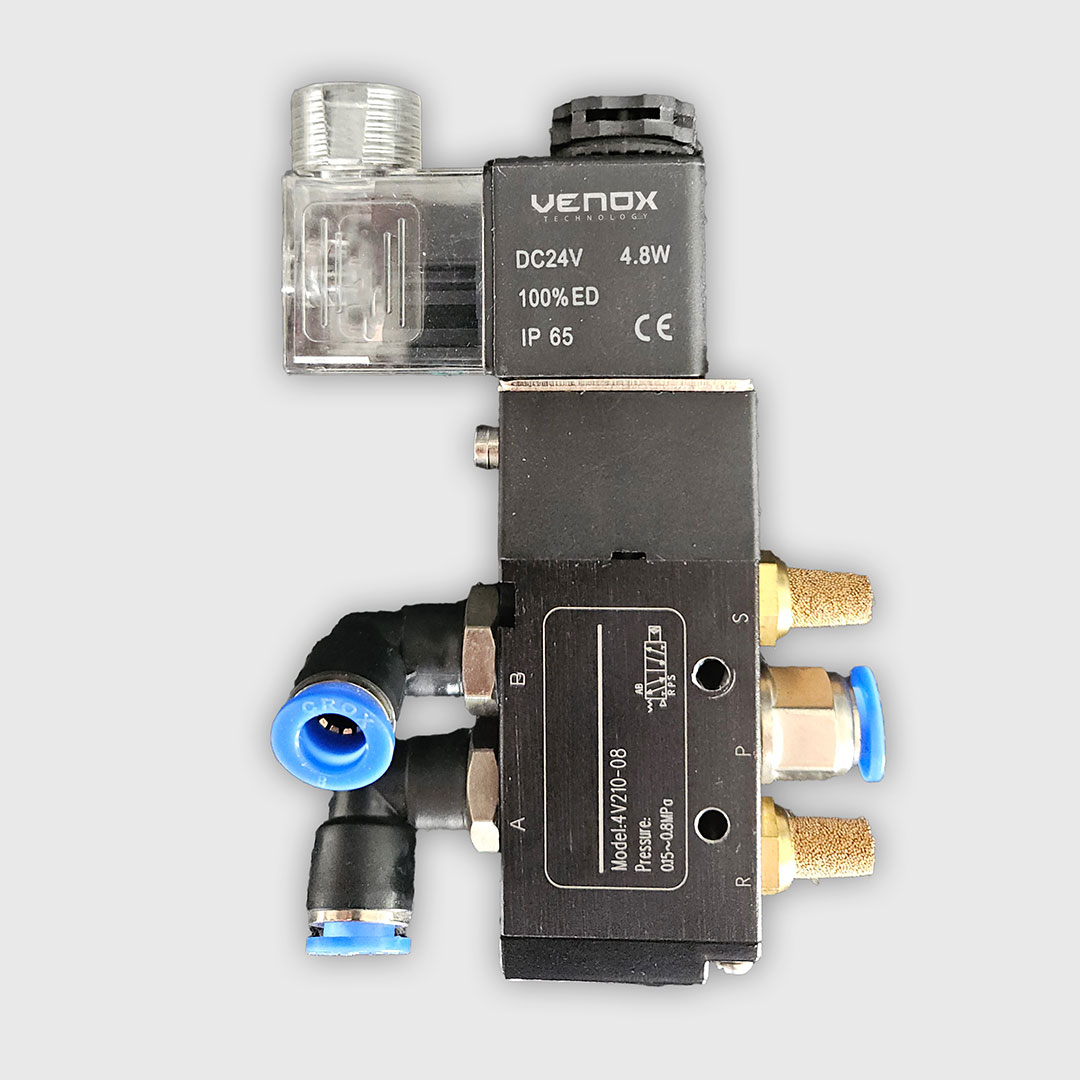

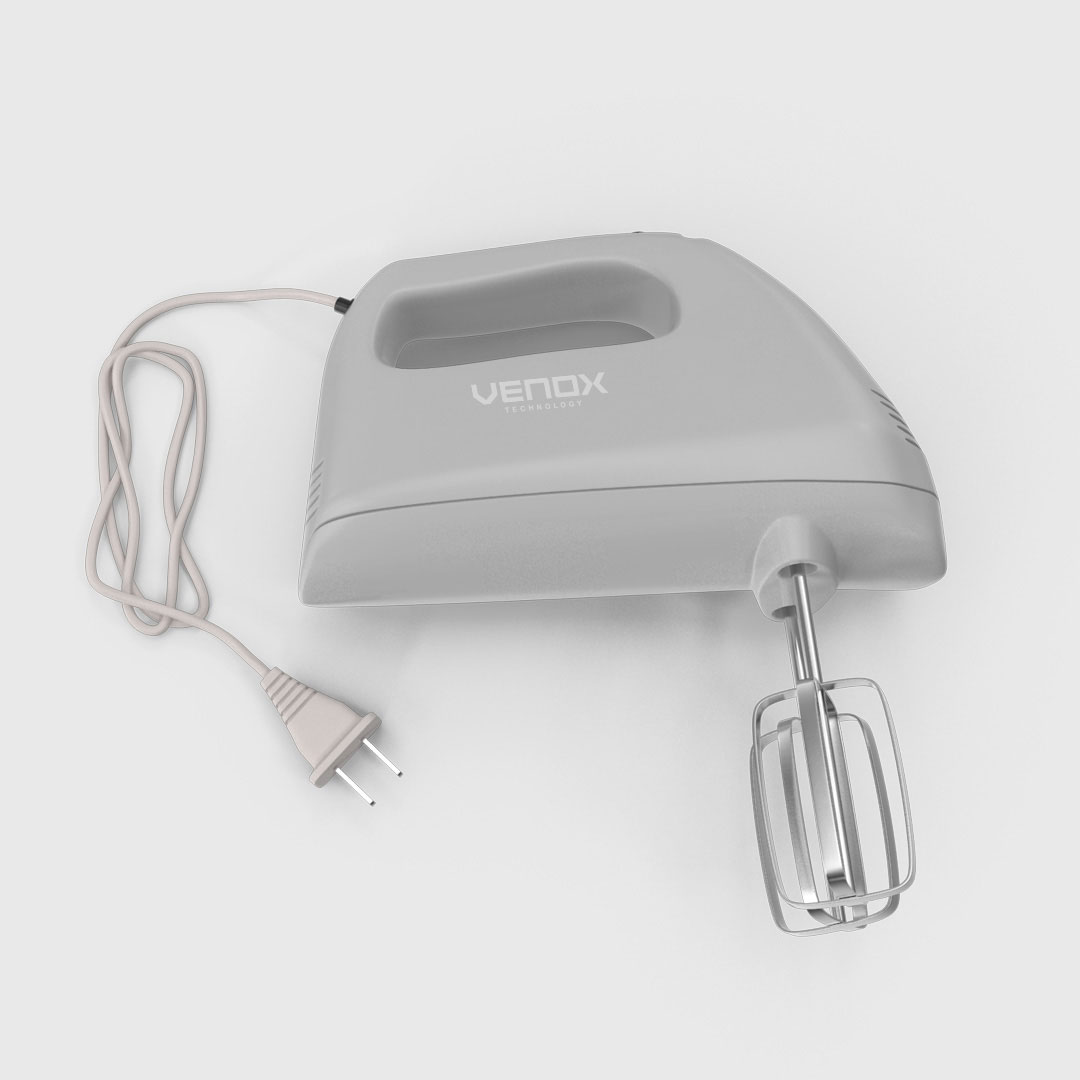

FE 20, as the 20 W configuration within Venox’s FE Series, is a fiber laser marker developed especially for small and medium-sized businesses with its compact body and cost-effective structure.

The general architecture of the FE Series is based on a space-saving laser head and a separate control unit; thus, the machine can either be integrated into an existing production line or used as a standalone station. Thanks to its robust mechanical structure and industrial electronic components, it aims to deliver long-lasting and stable performance in 24/7 production environments.

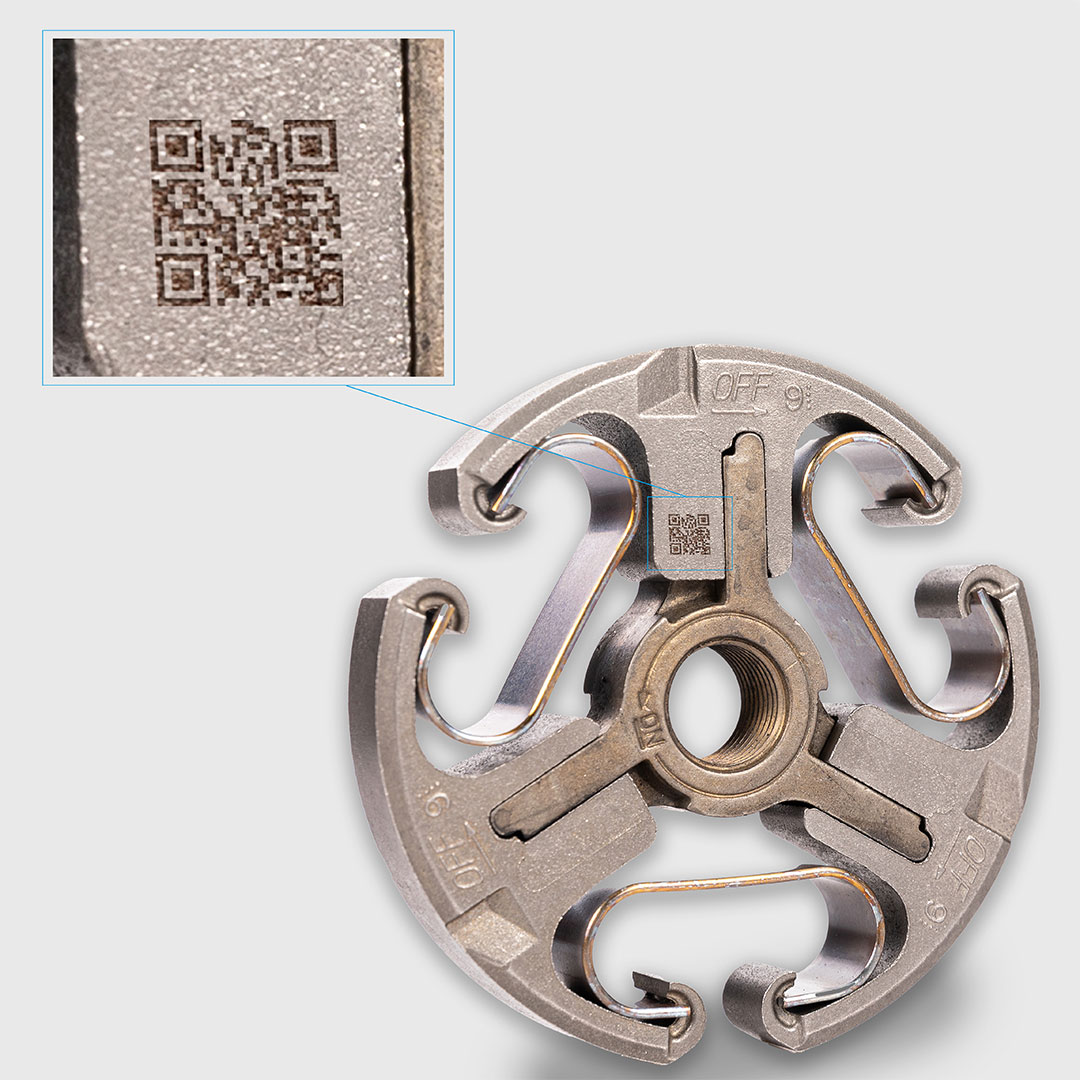

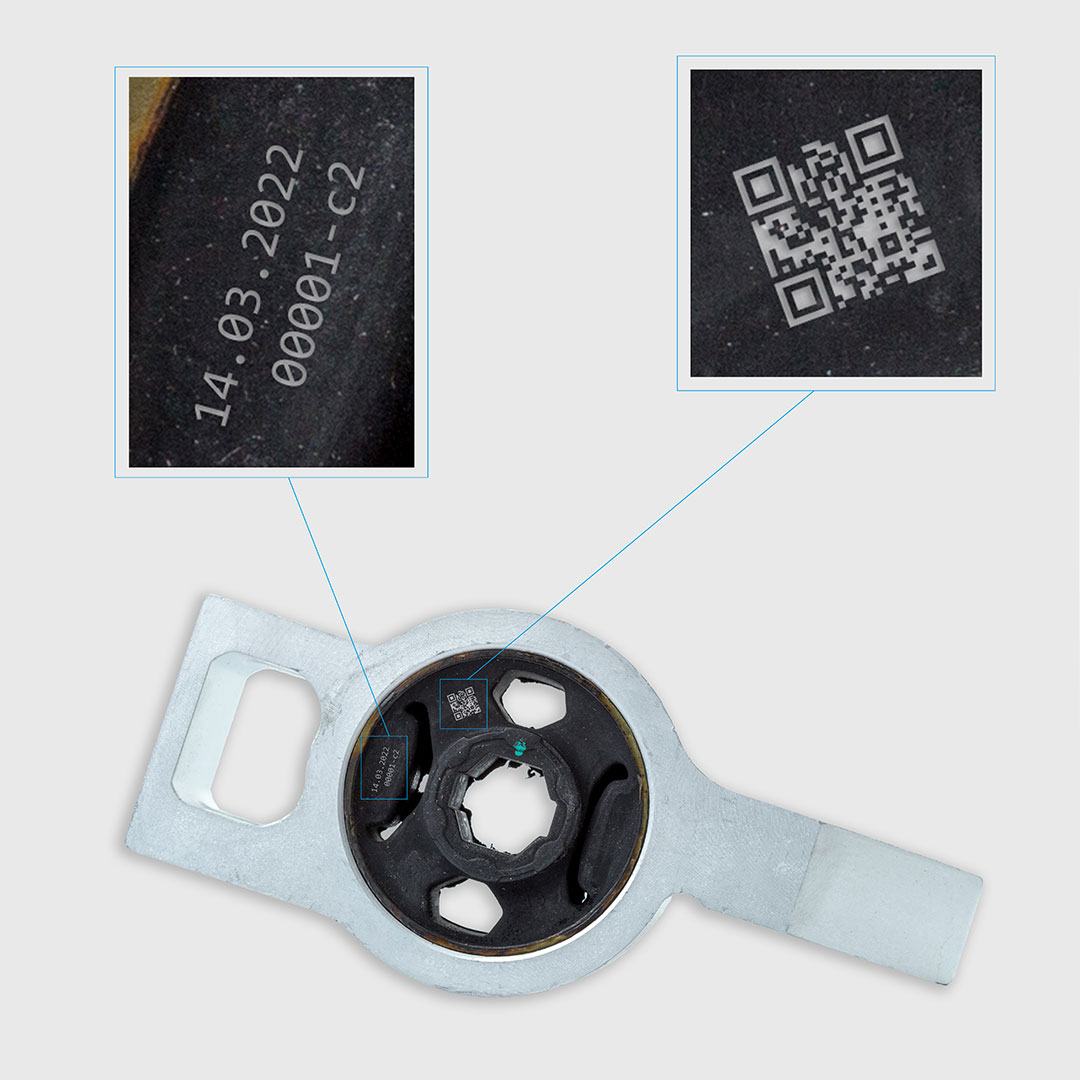

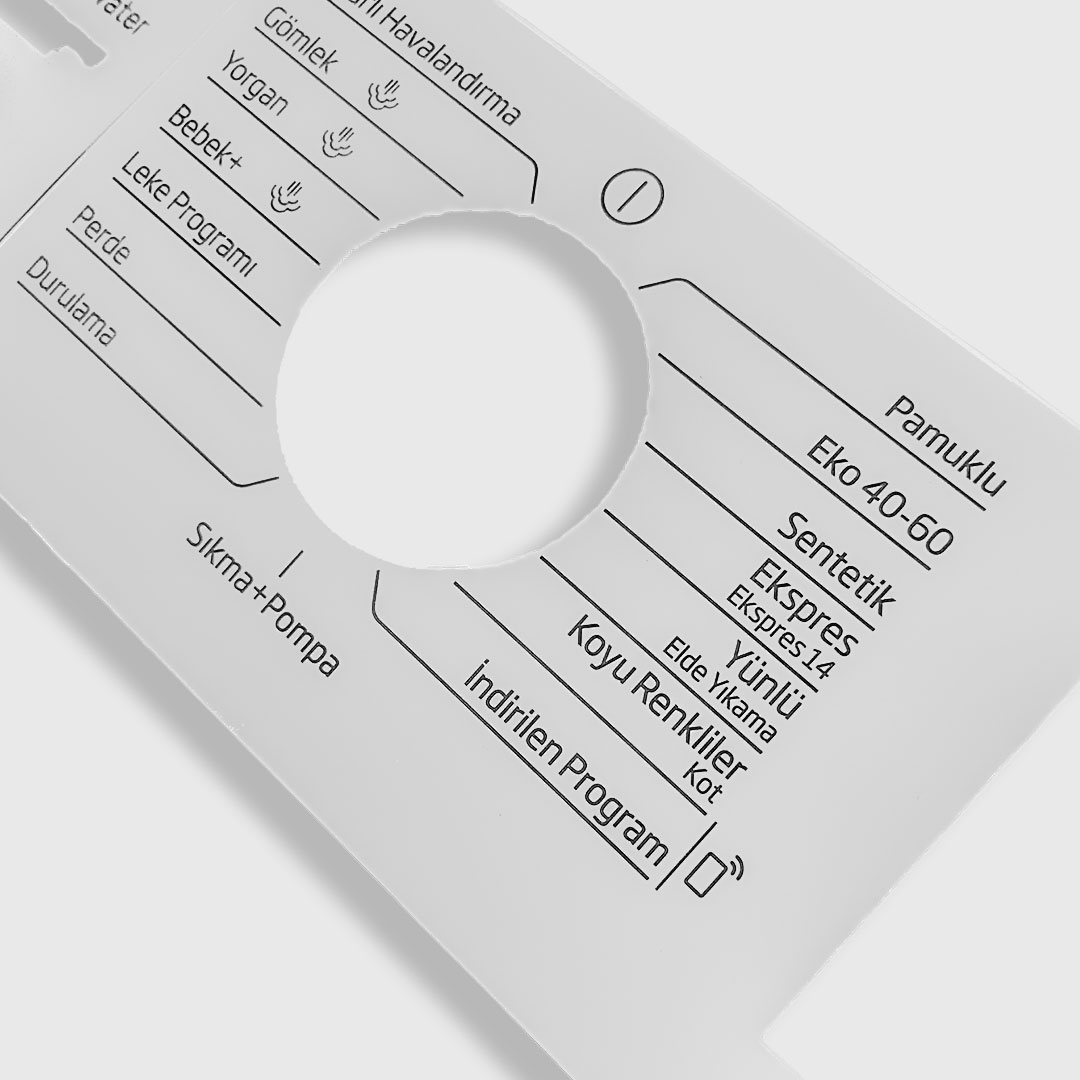

On the laser side, FE 20 can perform permanent, high-contrast, and wear-resistant marking on metal and many plastic surfaces with its fiber laser source operating at a wavelength of 1064 nm. This structure is ideal especially for industrial parts that require information such as serial numbers, QR codes, DataMatrix, logos, and text. By nature of fiber laser technology, since the heat input is well controlled during processing, markings with high edge sharpness in fine details and high readability are obtained. This makes it easier to meet the traceability standards demanded by sectors such as automotive, electronics, and medical.

In terms of application areas, FE 20 can be used in fields such as part and component coding in automotive, cable and connector marking, plastic button/panel marking in white goods, code printing on PCBs and components for electronics, and UDI and lot code marking on medical devices. Beyond metal and plastic, with suitable parameters, color change (annealing) or coating removal applications on some coated surfaces are also possible. This versatility of the FE Series provides important flexibility for businesses that want to meet marking needs at different points of the factory with a single machine.