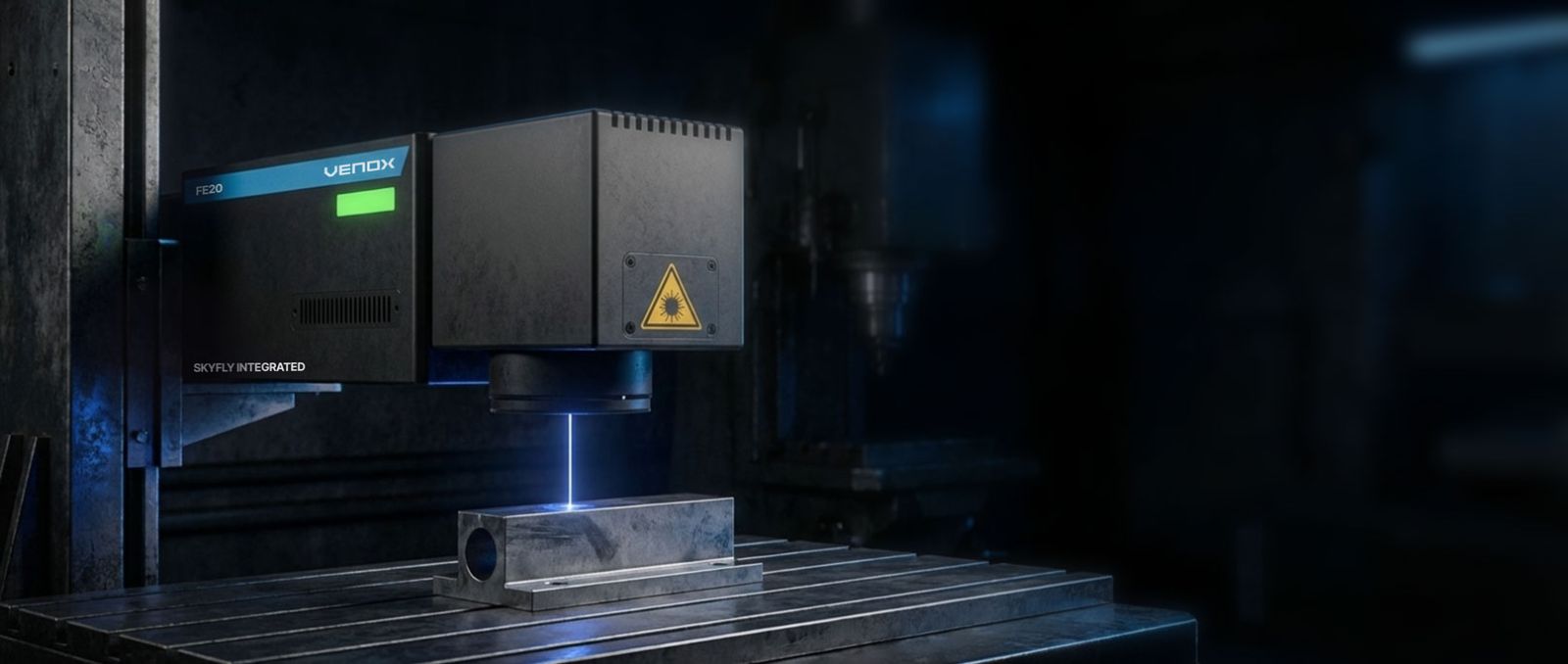

Automation and Inline Integration in Industrial Laser Marking Applications

The true strength of laser marking systems in industrial production emerges through inline automation and digital integration. Manual solutions may be sufficient up to a certain point; however, for scalable, traceable, and error-free production, integrating laser marking systems into production lines is critical. For Venox’s automation-compatible solutions: Laser Marking Machines.

Integration of Laser Marking Systems into Production Lines

Inline integration refers to laser marking stations becoming a natural part of the production line. This structure provides significant advantages in terms of speed, accuracy, and data continuity compared to manual applications.

PLC triggering and synchronized operation

Laser marking machines are triggered by PLC signals to mark the right part at the right time. This synchronization minimizes the risk of incorrect marking.

Compatibility with conveyor systems

In continuously flowing production lines, laser marking systems adapt to conveyor speeds. Clear and repeatable marking on moving parts becomes possible.

Robotic integration solutions

Laser marking stations integrated with robotic arms provide flexible application capabilities for parts with complex geometries. This structure offers advantages in lines producing multiple product variants.

Camera systems and verification

Post-marking camera inspection verifies readability, position, and data accuracy in real time. Defective parts can be automatically separated.

Variable data and recipe-based marking

Inline laser marking systems can automatically select recipes based on product type. Serial numbers, lot, and date information are updated without manual intervention.

MES and ERP integration

Laser marking data is transferred to MES and ERP systems. This enables centralized management of production performance and quality data.

Operational Benefits Provided by Automation

Automation in laser marking delivers not only increased speed but also advantages in quality, safety, and cost efficiency.

Elimination of human error

Automated systems largely prevent operator-related errors such as wrong product selection, incorrect codes, or incomplete marking.

Production continuity and reduced downtime

Inline laser marking minimizes unplanned downtime, as it does not require label changes or manual adjustments.

Standardized and repeatable quality

Thanks to automation, the same marking quality is maintained across every shift and operator change.

Real-time data and reporting

Marking performance, error rates, and production quantities can be monitored in real time. These data are used for continuous improvement.

Inline laser marking solutions with Venox

Venox designs and commissions laser marking systems specifically for production lines. To learn more about automation-compatible solutions, you can visit the Venox laser marking machines page.

Inline automation maximizes the speed, quality, and traceability potential of laser marking.

To plan and implement automation-compatible laser marking systems for your production line, you can contact Venox experts.