Checklist and Decision Tree for Laser Marking: How to Choose the Right System?

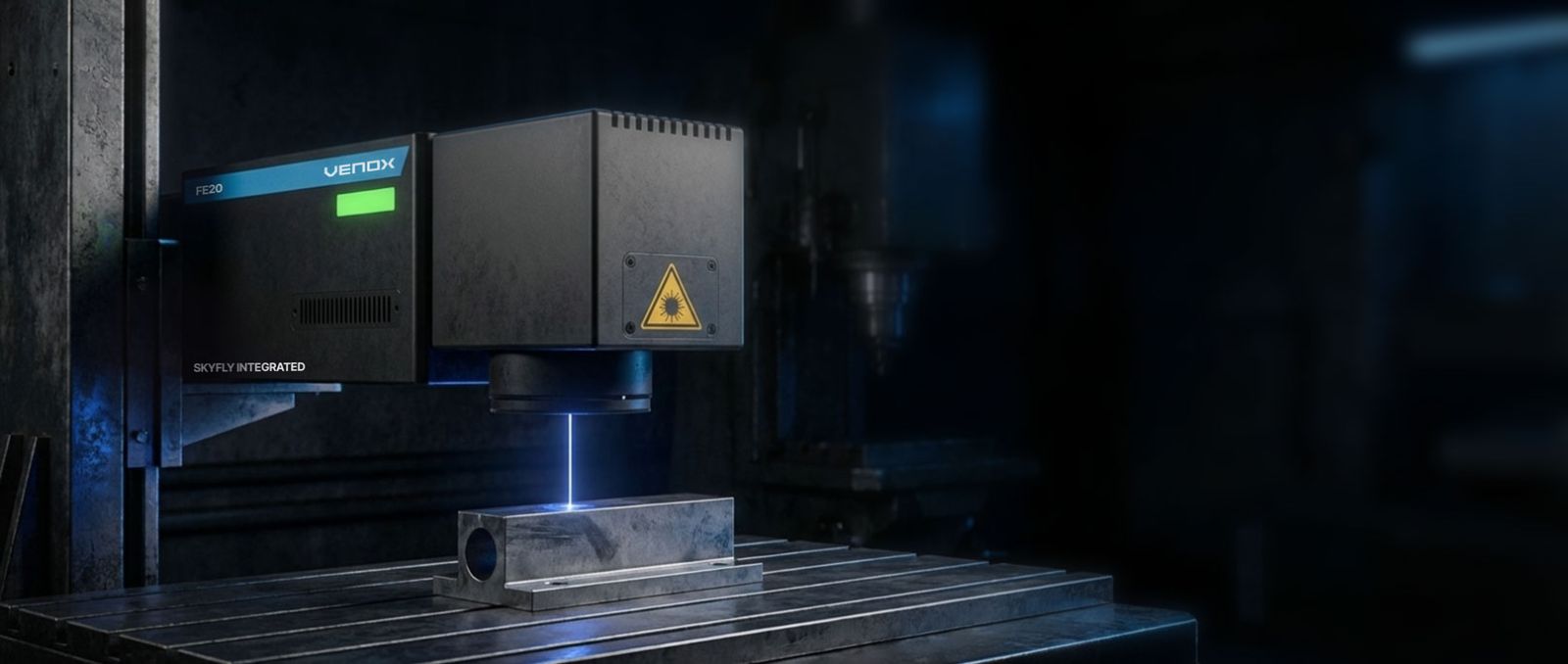

Asking the right questions before investing in laser marking helps prevent incorrect technology selection, unnecessary costs, and integration issues from the very beginning. This page provides a practical checklist and a step-by-step decision tree to help you identify the laser marking system that best fits your business needs. For Venox solutions: Laser Marking Machines.

Pre-Investment Checklist for Laser Marking

The checklist below helps you clearly define your technical and operational requirements before entering the purchasing process. Each of these points directly affects the system configuration.

1. What material will be marked?

Metal, plastic, glass, or composite surfaces are decisive factors in laser source selection. Choosing the wrong wavelength can lead to low contrast or surface damage.

2. Type of marking and durability expectation

Is surface marking, deep engraving, or high-contrast micro marking required? The product’s operating conditions (heat, chemicals, abrasion) determine this expectation.

3. Production speed and cycle time

The marking time must match the overall pace of the production line. In high-volume production, seconds become critical.

4. Marking area and part geometry

Part size, surface inclination, and access requirements affect lens selection, focal distance, and fixture design.

5. Manual or automated operation?

There are significant differences in both cost and efficiency between operator-based use and inline automation. Future automation plans should also be considered at this stage.

6. Traceability and data integration requirements

It should be determined whether serial numbers and codes such as QR/DataMatrix need to be linked with MES or ERP systems.

7. Safety and regulatory requirements

Safety enclosures, interlock systems, and fume extraction solutions must be evaluated in terms of occupational safety and regulatory compliance.

8. Service, maintenance, and local support

After-sales support, operator training, and spare parts availability are critical for long-term system performance.

Step-by-Step Laser Marking Decision Tree

The decision tree below helps convert the answers from the checklist into a practical selection. Each step clarifies the next technical choice.

Step 1: Identify the material type

Metal-based applications → Fiber laser Organic / non-metal surfaces → CO₂ laser Sensitive plastics and electronics → UV laser

Step 2: Define durability and contrast requirements

If harsh environmental conditions and long service life are required, deep or high-contrast laser marking should be preferred.

Step 3: Evaluate production volume

For low-volume production, manual or semi-automatic systems may be sufficient. Inline automation offers advantages in high-volume production.

Step 4: Select the integration level

Integrations such as PLC triggering, robotic arms, or camera verification may be preferred for traceability and error prevention.

Step 5: Verify safety and ergonomics

Operator safety, ease of access, and maintenance ergonomics directly affect daily system operation.

Step 6: Calculate total cost of ownership (TCO)

The most suitable system emerges when initial investment, operating costs, and production gains are evaluated together.

Clarify the decision process with Venox

Venox supports this checklist and decision tree with real applications and sample tests, helping companies make the right investment. To start the process: visit the Venox laser marking machines page.

Choosing the right laser marking system should be done through a systematic decision process, not randomly.

To review your laser marking checklist with Venox experts and create a clear roadmap for your production, you can contact Venox.