Digital Transformation, Industry 4.0, and Smart Manufacturing in Laser Marking Machines

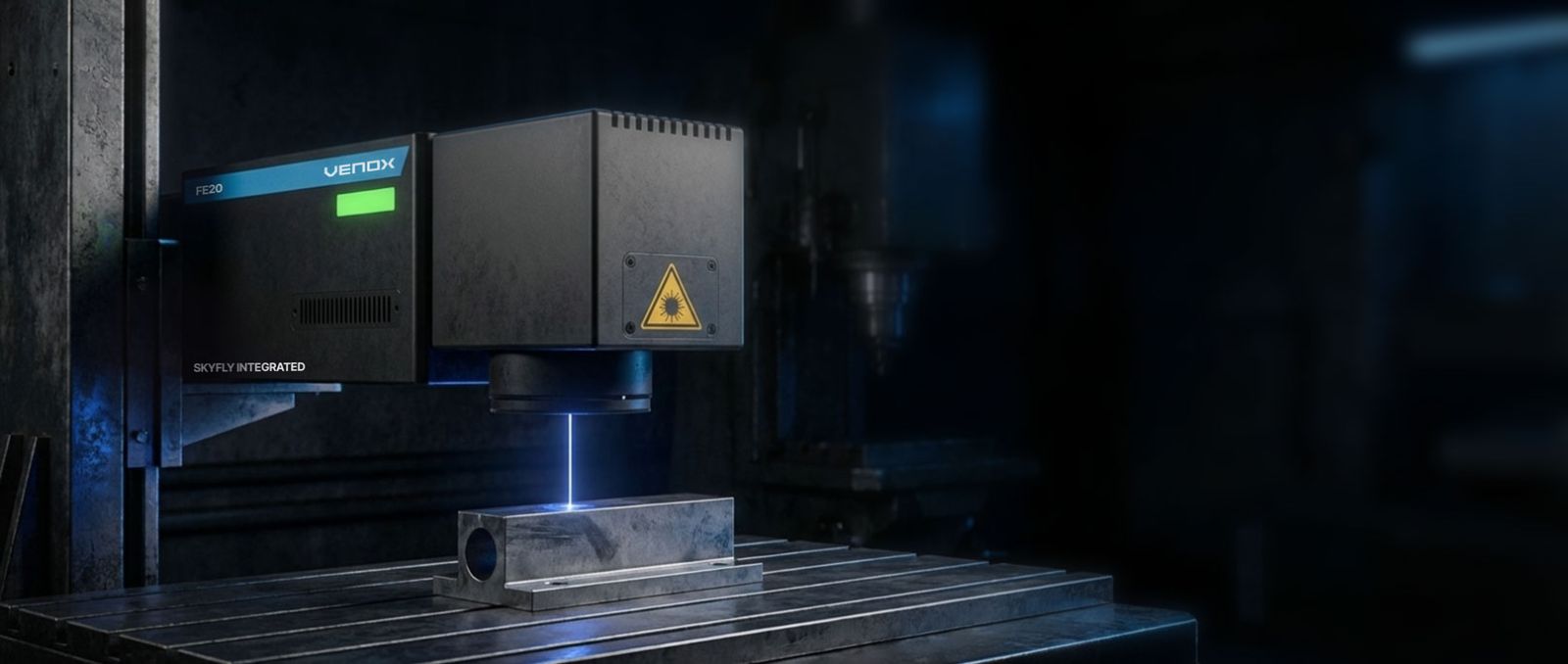

Competitive advantage in industrial production is no longer determined only by speed and quality, but also by digitalization and smart manufacturing capabilities. Laser marking machines are among the critical components that generate data and feed processes throughout the Industry 4.0 journey. For Venox’s digital transformation–ready solutions: Laser Marking Machines.

The Strategic Role of Laser Marking in Digital Manufacturing

Laser marking systems are not merely a physical marking point; they are the center where a product’s digital identity is created. This identity connects all processes from production to the field.

Creating a product-based digital identity

Serial numbers and 2D codes create the product’s counterpart in the digital world. This structure is one of the cornerstones of smart manufacturing.

Real-time data generation

Data generated during marking provides instant information about production speeds, error rates, and the causes of downtime.

Integration with cyber-physical systems

Laser marking machines work together with sensors, cameras, and PLCs, becoming part of cyber-physical production structures.

Standardization and process transparency

Thanks to digital records, every product is manufactured with the same quality and the same rules. Processes become transparent and auditable.

Industry 4.0–Compatible Laser Marking Applications

In smart factories, laser marking systems are in constant communication with other production components. This integration supports autonomous decision-making processes.

MES and data analytics integration

Marking data is analyzed through MES systems and used to improve performance and efficiency.

Autonomous quality decisions

With camera and software integration, products that do not meet quality criteria are automatically detected by the system.

Predictive maintenance and predictive analytics

Data collected from laser marking machines enables maintenance needs to be predicted in advance. This approach reduces unplanned downtime.

Cloud and remote monitoring infrastructures

Centralized monitoring systems make it possible to manage the laser marking performance of multiple facilities from a single dashboard.

Industry 4.0–compatible laser marking with Venox

Venox configures its laser marking machines in line with Industry 4.0 principles. For solutions that support your digital transformation journey, you can review the Venox laser marking machines page.

Digitalized laser marking enables data-driven decisions, high transparency, and smart manufacturing.

To elevate your production processes to Industry 4.0 and integrate your laser marking systems into your digital infrastructure, you can contact Venox experts.