Efficiency in Mass Production with Inline Laser Marking Machines

Basics of Inline Laser Marking

Inline laser marking machines mark parts moving on a conveyor without stopping product flow. With contactless operation, high speed, and low maintenance advantages, they meet takt time targets in mass production and ensure traceability (GS1/UDI), quality, and data integrity.

Mark-on-the-Fly (MOTF) and Takt Time

Mark-on-the-Fly (MOTF) synchronizes the laser pattern with the product's movement. With proper encoder integration, speed compensation, and scanning strategy, the cycle time per part is reduced and efficiency losses due to start-stop motion are eliminated.

Sensor and Triggering: Stable Start Condition

- Part detection: Position reference via photoelectric/inductive sensor.

- Delay compensation: Delay/offset adjustment based on sensor-to-laser distance.

- Multiple products: Dynamic trigger windows based on product length.

Encoder Integration: Speed and Distance Synchronization

- Line speed measurement: Real-time speed compensation via encoder signal.

- Scale/jitter: Pulses per turn and mechanical drift calibration.

- Engraving accuracy: Ensuring same code size/position on every part.

Positioning: Repeatability without Fixtures

To tolerate part variation within the field of view (F-Theta), marking windows, fiducial/edge detection, and vision-assisted offset correction are used. This improves repeatability even in fixtureless production.

Optics and Field: Lens, Spot Size, Working Distance

- Field selection: F-Theta lenses ranging from 100×100 to 300×300 mm.

- Spot/resolution: Smaller spot = finer lines, but narrower field.

- Focus management: Dynamic Z-axis/auto-focus for varying heights.

Hatch and Scan Strategy: Speed–Contrast Balance

Hatch spacing, number of layers, and scan direction (0°/45°/90°) are optimized along with MOTF synchronization. Multi-pass strategies are used for high contrast (stainless steel) or deep engraving (aluminum).

Vision Verification: Code Quality and Readability

- 2D codes: ISO/IEC 15415 for Datamatrix/QR, 15416 for 1D barcodes.

- OCR/OCV: Text verification, wrong data, and rotation control.

- Red/Sort station: Automatic rejection of defective parts.

MES/ERP Integration: Data Flow and Traceability

Variable data (lot/serial), job order, and routing information are received via REST API/OPC UA; printed data and quality grades are fed back. Thus, part history is tracked with unique identity.

PLC and HMI: Operational Control

- Status management: Start/Stop/Alarm, interlock and safety circuits.

- Recipe management: Product parameters, lens/focus, and power settings.

- Station handover: Fast switching for multi-line/multi-product production.

Safety and Filtration: Class 1 Operation

Class 1 enclosure, light sealing, fume/particle filtration (HEPA/activated carbon), and safety interlocks are mandatory for operator protection and regulatory compliance.

Maintenance and TCO: Near-Zero Downtime Goal

- Routines: Lens cleaning, galvo calibration, focus/power checks.

- Spares: Filter, lens, and fan stock plan; preventive maintenance schedule.

- Log analysis: Data-driven reduction of error/downtime root causes.

Commissioning Checklist

- Sample set and target contrast/depth – approved parameter recipe

- Encoder/sensor placement – offset and jitter calibration

- Vision verification – target quality grade and red/sort logic

- PLC–MES data map – serial/lot, job order, and feedback fields

- Safety and filtration – CE/UL requirements, Class 1 approval

FAQ: “Makinaları” or “Makineleri”?

Both versions generate search volume. While “makineleri” is more common in technical writing, including “lazer markalama makinaları” naturally improves SEO visibility.

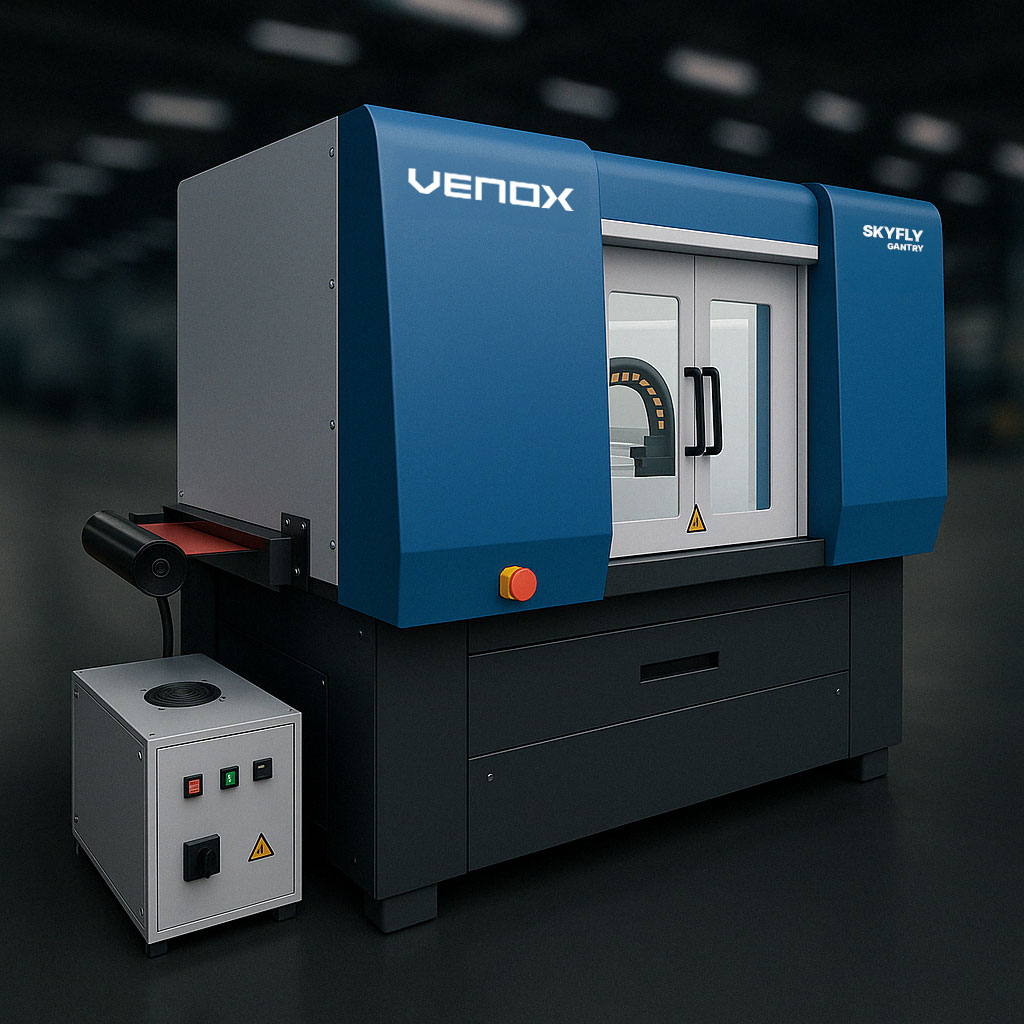

Inline Success with Venox

Contact us for inline laser marking solutions with Mark-on-the-Fly, vision verification, and MES/ERP integration. Explore our products: Laser Marking Machines.