What Is Epoxy Laser Ablation?

Definition

Epoxy laser ablation is the controlled removal of an epoxy coating using a laser beam on epoxy-coated surfaces. This method exposes the underlying metal or plastic layer to create clear and permanent markings.

Working Principle

The laser beam removes the epoxy coating with micron-level precision. In this way, markings such as logos, barcodes, QR codes, text, or patterns appear in high resolution.

Advantages of Epoxy Laser Ablation

Effective on Durable Coatings

Epoxy coatings are highly resistant. The laser ablation method enables high-contrast marking even on these hard coatings.

High Contrast and Readability

When the coating is removed, the underlying surface becomes clearly visible, helping the markings remain readable for a long time.

No Need for Chemicals

There is no need for the chemical solvents used in conventional stripping methods. This feature supports environmentally friendly production.

Permanent Solution

Markings made by epoxy laser ablation are resistant to abrasion, heat, and chemicals.

Applications

Electronics Industry

On epoxy-coated printed circuit boards (PCBs) and chips, serial numbers, barcodes, and QR codes can be applied.

Automotive Industry

Permanent marking is achieved on epoxy-coated metal parts. This method is critical for traceability and quality control processes.

Medical and Industrial Devices

Permanent markings that withstand sterilization can be applied to epoxy-coated medical devices and industrial equipment.

Energy and Defense Industry

Epoxy-coated parts are widely used in the defense industry. Laser ablation is a reliable method for identifying these parts.

Epoxy Laser Ablation Methods

Selective Ablation

Only the epoxy layer in specific areas is removed to create high-contrast markings.

Full Coating Removal

The entire coating is removed to fully expose the underlying surface.

Multi-Layer Processing

Epoxy layers of different thicknesses are removed gradually to create patterns at varying depths.

Technical Features

Laser Types

Fiber lasers are generally preferred. For high-precision applications, UV lasers can also be used.

Precision

Provides micron-level control, enabling the processing of finely detailed barcodes and QR codes.

Marking Area

Different working field options are available, such as 110×110 mm, 200×200 mm, and 300×300 mm.

Automation Integration

Can be integrated into inline laser marking systems for use on high-volume production lines.

Machine Selection Criteria

Coating Thickness

The laser power and focusing should be selected according to the thickness of the epoxy layer.

Material Type

The laser source should be chosen based on the metal or plastic surface beneath the epoxy coating.

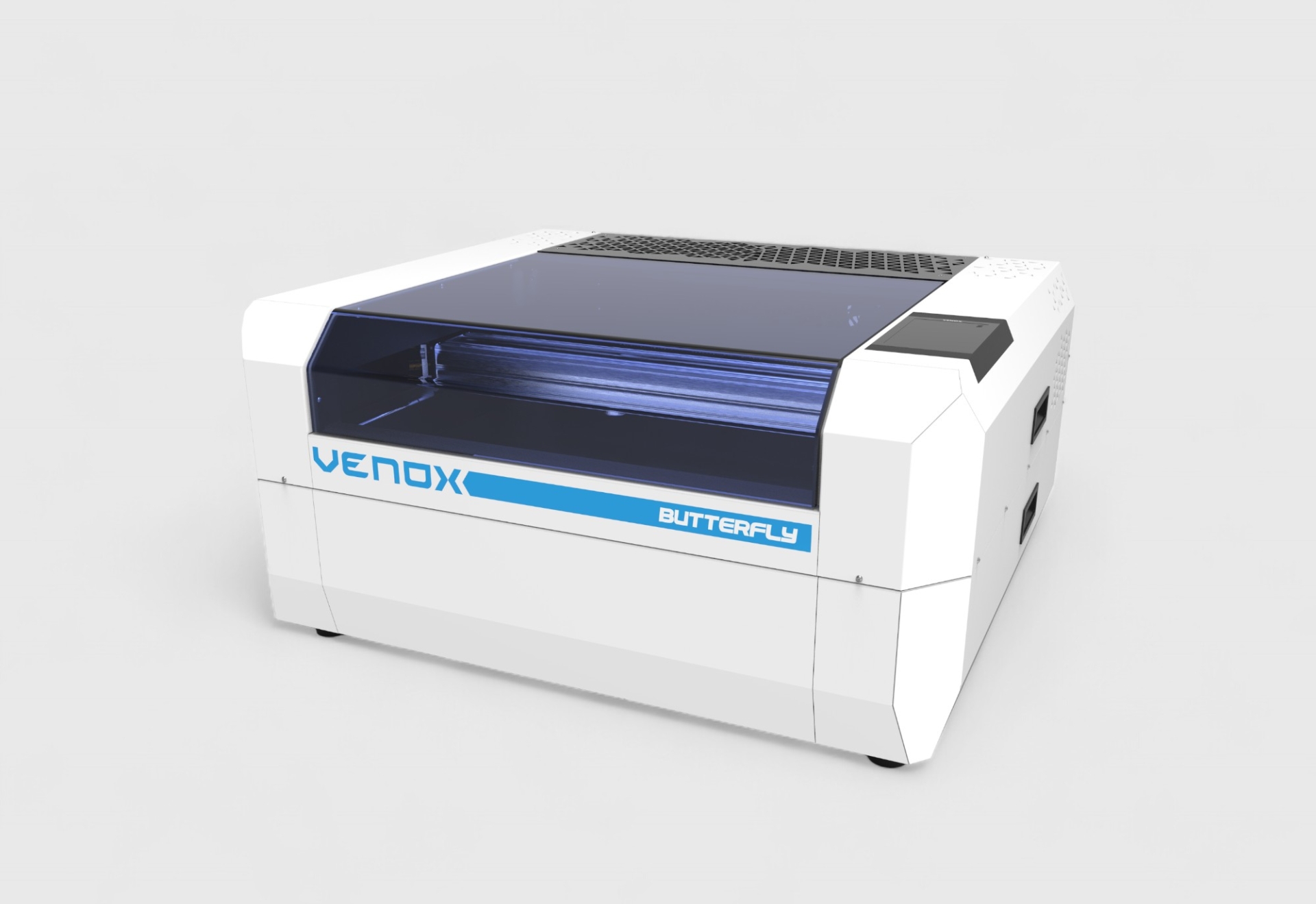

Production Capacity

For small-scale production, desktop machines are suitable; for mass production, industrial machines are appropriate.

Quality Control

The readability of the markings should be tested with integrated camera systems and integrated into quality assurance processes.