Glass is a material that is difficult to process due to its fragile structure. However, thanks to advances in technology, this challenge can now be easily overcome with high-precision laser systems. Especially in industrial production, Glass Laser Cutting Machines are revolutionizing glass processing by offering both aesthetic and functional excellence. The advanced laser systems provided by Venox Teknoloji are capable of processing the complex structure of glass down to the finest details.

What Are Glass Laser Cutting Machines?

Glass laser cutting machines are high-tech systems that perform cutting by focusing a laser beam to create melting, evaporation, or micro-cracking on the glass surface. Thanks to their contactless cutting feature, the risk of glass breakage is minimized. These machines make it easy to process complex shapes, holes, text, patterns, and contours on glass surfaces.

Why Choose Glass Laser Cutting Machines?

Laser cutting technology offers unique advantages that deliver excellent results on delicate materials like glass:

- Cutting without the risk of breakage or cracking

- Micron-level precision

- Clean edges that require no additional polishing or finishing

- Ability to integrate with automation systems

- High speed and suitability for mass production

- Production without chips, dust, or physical contact

Which Industries Are They Suitable For?

Glass laser cutting machines are used across a wide range of industries:

Architecture and Interior Design

They provide high-resolution cuts for decorative glass panels, partitions, mirrors, and custom-patterned glass applications. For example, specially patterned glass used in hotel lobbies is flawlessly produced with these machines.

Automotive and Transportation Industry

They meet the need for high-precision and fast cutting in products such as car windows, train windows, and specialized safety glass.

Electronics and Optical Products

They deliver micrometer-level cutting precision for phone screens, sensor surfaces, and optical lens coatings.

Furniture and Home Appliance Manufacturing

They ensure dimensional accuracy and visual quality in aesthetic and functional parts such as glass shelves, stove glass, and oven doors.

Laboratory and Medical Glass

High-precision cutting and drilling processes can be carried out on products such as medical tubes, microscope slides, and glass pipettes.

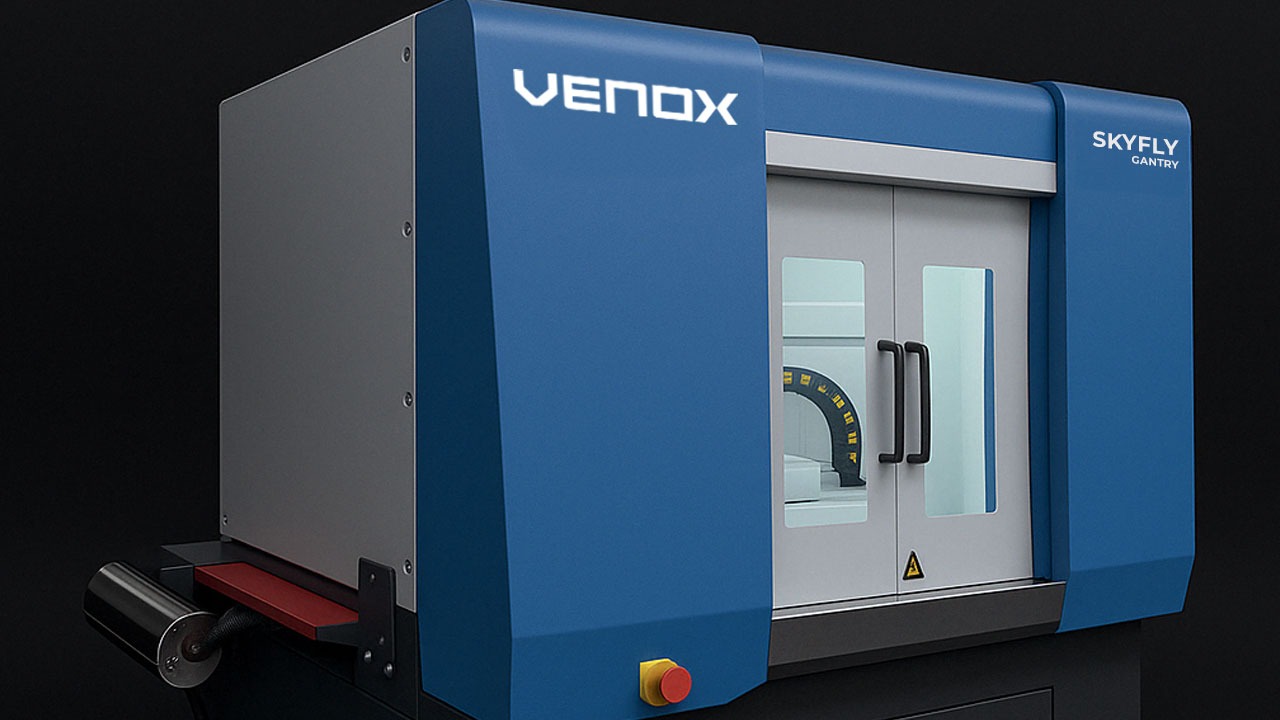

Venox Teknoloji’s Laser Cutting Solutions

Venox Teknoloji specializes in machines used for industrial glass cutting. Its extensive product range offers systems tailored to every need:

- Laser Marking Systems

- Laser Marking Machines

- Laser Cutting Systems

- Laser Cutting and Marking Machines

- Custom Solutions

Types of Lasers Used in Glass Cutting

Two main laser technologies are generally preferred for glass processing:

- CO₂ Lasers: Operate in the infrared spectrum. Provide cutting through thermal effects and evaporation. Effective for thick glass.

- Ultrashort Pulse Lasers: Have minimal heat diffusion. Ideal for thin glass and micro-cutting applications.

Venox Teknoloji offers solutions suitable for both technologies, guaranteeing optimum performance for different types of glass.

What to Consider When Choosing a Glass Laser Cutting Machine?

Considering the following criteria when investing in a glass laser cutting machine ensures long-term efficiency:

- Laser power and wavelength

- Cutting area and table size

- Automatic loading/unloading systems

- Cooling unit and safety features

- CNC control software

- Service and technical support infrastructure

Industry 4.0 Compatible Systems

The laser machines offered by Venox are designed to meet the digitalization needs of today’s production facilities. Thanks to their IoT-compatible infrastructure, the machines can monitor production data in real-time, integrate with automation systems, and be managed remotely.

Sustainability with Glass Laser Cutting

Laser cutting technology is an environmentally friendly production method. It does not use chemicals, and chip or waste generation is kept to a minimum. Combined with the recyclable nature of glass, these machines become an essential part of sustainable production.

Application-Specific Designs

Not every glass cutting need is the same. For this reason, Venox Teknoloji develops laser systems tailored to the project. For example:

- Special density settings for tempered glass

- Multi-layer cutting for laminated glass

- 3D configurations for curved glass

For such customized solutions, you can visit the Custom Solutions page for detailed information.

Conclusion: The Path to Perfection in Glass Leads Through Venox

Glass laser cutting machines are an indispensable technology for companies seeking precision, speed, and flexibility in production. The innovative machines offered by Venox Teknoloji are redefining the boundaries of this field and providing businesses with quality, efficiency, and sustainability.

If you want to digitalize your glass cutting processes and integrate high technology into your production lines, you can contact Venox Teknoloji to explore customized solutions.