Industrial Laser Marking: Application Types, the Right Technology by Material, and Venox Solutions

In industrial production, laser marking plays a critical role in traceability, quality standardization, and operational efficiency. Data such as serial numbers, QR/Datamatrix codes, logos, date codes, and batch information are applied quickly, permanently, and legibly, enabling products to be tracked throughout their entire lifecycle. For Venox’s industrial solutions: Laser Marking Machines.

Key Parameters That Determine Success in the Laser Marking Process

In laser marking, the “right process” is just as important as the “right machine.” Material type (metal/plastic/composite), surface condition (anodized, coated, painted), target contrast level, marking speed, and required permanence directly influence the laser source and its parameters. In addition, a properly designed fixture, focus, and triggering setup within the production line are indispensable for error-free marking.

Laser machine selection criteria

During selection, material compatibility, marking area, cycle time, line integration, safety enclosure requirements, and the continuity of service and spare parts should be evaluated together. This approach optimizes not only the initial investment cost but also the total cost of ownership (TCO).

Marking quality and readability standards

Especially in barcode/QR/Datamatrix applications, readability is achieved through module clarity, contrast, and control of surface deformation. To avoid scanning issues from production to shipment, process parameters must be standardized.

In-line integration and automation

When the laser marking station is integrated with conveyors, robots, camera verification systems, PLC triggering, and production software, a more reliable workflow is established. This reduces the risk of “wrong part–wrong code” and simplifies trace-back and quality reporting.

Traceability and quality management in production

Laser marking is one of the fundamental tools for creating product identity within quality management systems (QMS). Markings matched with serial numbers and batch data provide significant advantages in error analysis, recall management, and customer satisfaction processes.

Safety and occupational health

Laser class, enclosure design, fume extraction (filtration), and operator access control are critical elements of workplace safety. In industrial use, proper safety configuration is essential for both sustainable operation and regulatory compliance.

Total cost: investment, maintenance, and consumables

Laser marking offers cost advantages in many applications by reducing consumables such as labels, inks, and solvents. However, factors such as optical component lifetime, periodic maintenance, filter replacements, and scheduled service should be included in the investment evaluation.

Laser Marking Applications by Material and Industry

Laser marking technology can be customized according to different material behaviors. While high contrast can be achieved on metals through deep engraving or surface oxidation, plastics may require minimizing surface deformation through low thermal impact. Industry-specific needs determine the type of marking: traceability in automotive, sterilization resistance in medical, and precision marking in electronics come to the forefront.

Metal laser marking applications

Laser marking on stainless steel, aluminum, and various alloys offers high resistance to mechanical abrasion, heat, and chemicals. Serial numbers, logos, and quality codes remain permanently on the product and enhance field readability.

Contrast and permanence on stainless steel

To achieve clear contrast on stainless steel, the correct balance of power/speed/frequency, appropriate lens selection, and surface preparation are essential. The right process can simultaneously deliver both aesthetic quality and industrial readability.

Aluminum and anodized surfaces

On anodized aluminum surfaces, the laser can create high-contrast markings by selectively affecting the coating. With suitable parameters, excessive burning or unwanted surface marks are minimized.

Laser marking on plastics: points to consider

Laser marking on plastics can vary depending on the material’s additive composition and surface behavior. Low thermal impact, the correct wavelength, and a controlled parameter set reduce the risk of cracking, melting, or deformation.

Automotive industry laser marking

In automotive production, laser marking is a standard method for traceability and quality records throughout the supply chain. Data such as part identity, production line codes, and serial numbers are applied quickly and repeatably.

Medical industry laser marking

Permanent marking on medical devices must withstand sterilization processes and reliably carry product identity. Process optimization plays a critical role in achieving clean markings on sensitive surfaces.

Laser marking on electronics and precision components

Laser marking on electronic components requires high resolution on small surfaces. Low thermal impact and precise focus control help achieve clear markings without affecting component performance.

Packaging and high-speed coding applications

In packaging, boxes, and labeling processes, date codes, batch numbers, and variable data can be applied rapidly. Triggering and automation compatible with production speed reduce stoppages and increase efficiency.

Cable, wire, and extrusion lines

In continuous-flow cable and wire lines, correct timing of laser triggering and stable focus control are essential. This ensures that codes are applied consistently along the flow and readability is maintained.

Laser engraving and deep marking requirements

Deep engraving is preferred in applications where markings must remain readable even under harsh environmental conditions. Material hardness, coating structure, and required depth necessitate careful adjustment of power and speed parameters.

Logo and brand identity applications

Laser logo marking strengthens the product’s premium perception and ensures lasting brand visibility in the field. For optimal results, vector file preparation, correct resolution, and an appropriate scanning strategy are important.

QR, Datamatrix, and serial number applications

The most common approach to traceability goals is the combined use of serial numbers and 2D codes. Codes linked to production data provide major advantages in quality management, warranty tracking, and service processes.

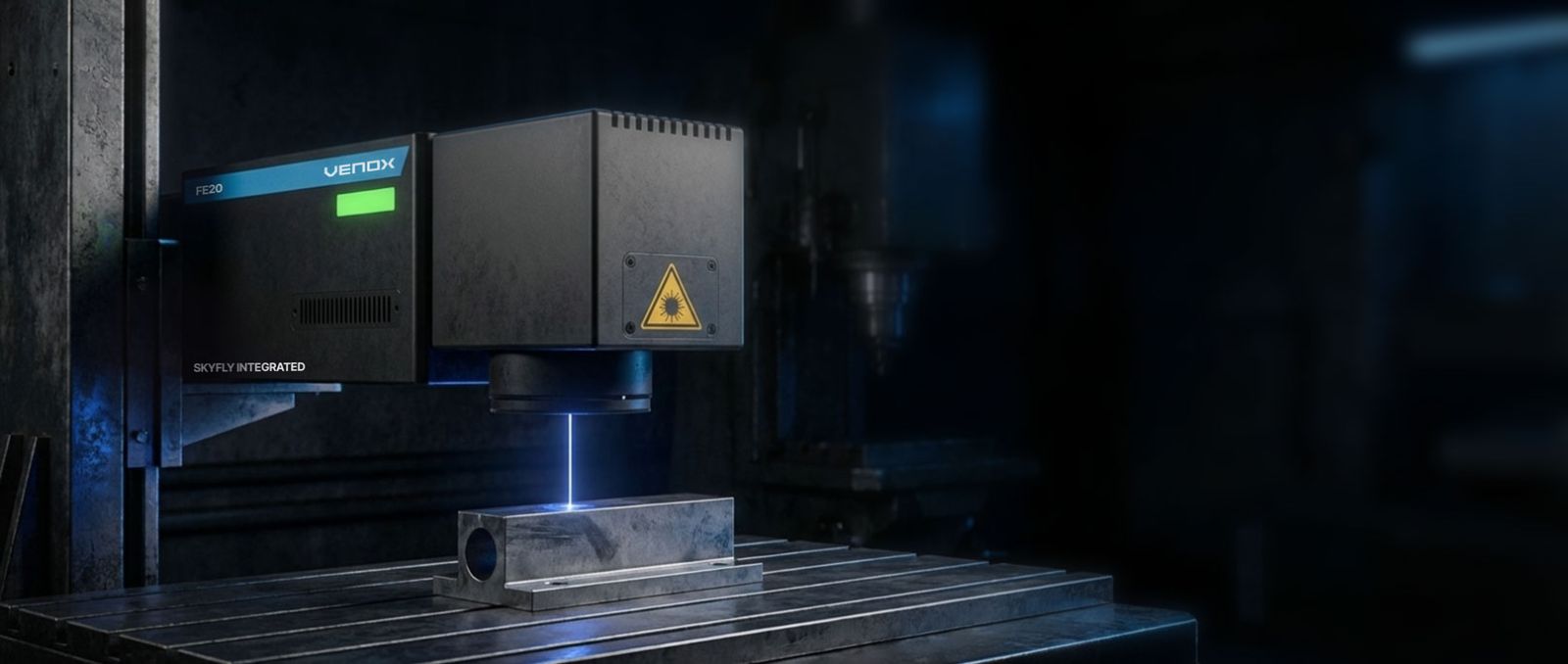

The right solution with Venox laser marking machines

With laser marking solutions tailored to the needs of industrial production, Venox supports the establishment of fast, permanent, and readable marking processes. To select the right technology and line integration for your application, you can review the Venox page: Laser Marking Machines.

A successful laser marking project is not only about machine selection, but also about planning sample testing + process standardization + integration + verification together. With Venox, you can evaluate solutions suitable for your production line and strengthen your traceability and quality objectives.

If you are planning an industrial laser marking investment, start with the Venox laser marking machines page to determine the most suitable configuration based on your material, target marking type, and line speed.