Definition of Laser Glass Cutting Technology

The Role of Laser in Modern Production

Laser glass cutting is a non-contact manufacturing method that uses the high-intensity energy of light to precisely cut glass surfaces. Compared to traditional diamond-tipped cutting or mechanical drilling systems, this method offers cleaner edge surfaces, lower risk of breakage, and high dimensional accuracy.

How Does It Work?

When the laser beam is focused on the glass surface, intense heat energy is generated at the focal point. This energy creates thermal stress on the glass surface, and the material is cut using the thermal separation method. Supported by a cooling gas or airflow, the fracture line is directed along the desired path.

Types of Lasers Used

CO₂ Laser Cutting

This is the most commonly used laser type for glass surfaces. CO₂ lasers with a wavelength of 10.6 µm are easily absorbed by glass and perform cutting efficiently.

Ultrashort Pulse (USP) Lasers

Picosecond (ps) and femtosecond (fs) lasers minimize micro cracks and fractures by creating heat-free zones. They are especially preferred in electronic and optical glass applications.

Fiber Lasers

Rather than cutting glass directly, they are used for marking, drilling, or surface processing on glass. They are highly effective on glass parts with metal frames.

Advantages of Laser Glass Cutting

High Cutting Quality

The edge surface is smooth, notch-free, and clean enough to eliminate the need for polishing. This significantly improves quality in glass displays, optical components, and decorative products.

Non-Contact Processing

Since there is no physical contact with the glass during cutting, mechanical stress does not occur. This preserves the structural integrity of the material.

Low Material Waste

Laser cutting minimizes material waste due to its very low margin of error. Each part is produced with the same quality using digital programming.

High Repeatability

Thanks to computer-controlled systems, the same design can be repeated thousands of times with identical precision.

Application Areas

Electronics and Display Manufacturing

Smartphone screens, tablet panels, sensor glass, and micro-optical components are shaped using laser glass cutting. USP lasers have become standard in this segment.

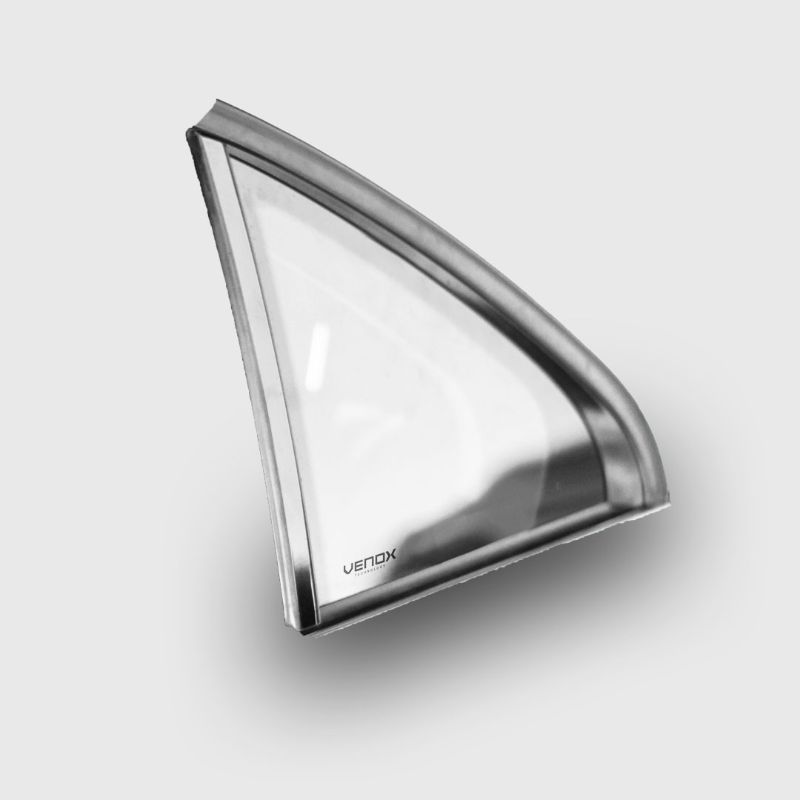

Automotive Industry

Laser cutting is preferred in dashboard displays, headlight glass, sensor covers, and decorative interior panels. It provides high-speed precision processing.

Furniture and Decoration

Glass tabletops, mirrors, display panels, and decorative dividers are precisely cut with lasers. It eliminates the need for edge polishing.

Optical and Laboratory Equipment

Glass slides, cover glasses, tubes, and custom laboratory glassware are produced via laser cutting. Thermal control minimizes crack formation.

Laser Glass Cutting Process

1. Material Analysis

The type of glass (float, borosilicate, tempered, etc.) is identified. Since each material has different thermal conductivity and expansion rates, laser parameters are adjusted accordingly.

2. Parameter Adjustment

Cutting speed, laser power, focal length, and cooling airflow are optimized. A precision of 0.1 mm can be achieved.

3. Thermal Management

Heat and cold airflow are balanced along the laser path. This prevents unwanted cracks from forming on the glass.

4. Edge Cleaning

Ionized air or light brushing can be applied to remove microscopic roughness on post-cut surfaces.

5. Quality Control

Edge smoothness and cutting accuracy are inspected with optical sensors or camera systems. All measurements are digitally recorded.

Laser Glass Cutting Machines

Industrial Systems

Venox Laser Cutting Systems can be easily integrated into mass production lines with high-speed galvo scanners, automatic focus sensors, and cooling-assisted optical heads.

Multi-Axis Solutions

3-axis or 5-axis laser heads provide high-precision cutting on inclined or three-dimensional glass surfaces. This technology is used in automotive and aerospace applications.

Compact Models

Compact desktop laser cutting machines are ideal for small production volumes and deliver efficient results with low energy consumption.

Technical Parameters

Laser Power

Generally ranges between 30W – 150W. Low power is preferred for thin glass, while higher power is used for thick glass.

Cutting Speed

Varies between 100 – 800 mm/s depending on material thickness. Multi-pass cutting may be used in high-speed systems.

Focus Adjustment

Accurate focusing prevents surface burns and improves edge quality. Automatic Z-axis tracking optimizes this process.

Safety and Maintenance

Operational Safety

Eye protection, fume extraction systems, and safety sensors are used during laser cutting operations. These components are essential for occupational safety.

Ease of Maintenance

Laser tubes, mirrors, and lenses must be cleaned regularly. Thanks to dust-free optical housing designs in modern systems, maintenance time is minimized.

Conclusion

Laser glass cutting stands out in industrial production with advantages such as high accuracy, low cost, and environmentally friendly processing. With Venox laser cutting and marking machines, manufacturers of all scales can easily integrate this technology and bring their glass processing operations into the digital age.