Laser Marking Machine: Permanent and Fast Marking Technology in Industrial Production

What is a Laser Marking Machine?

Definition and Function

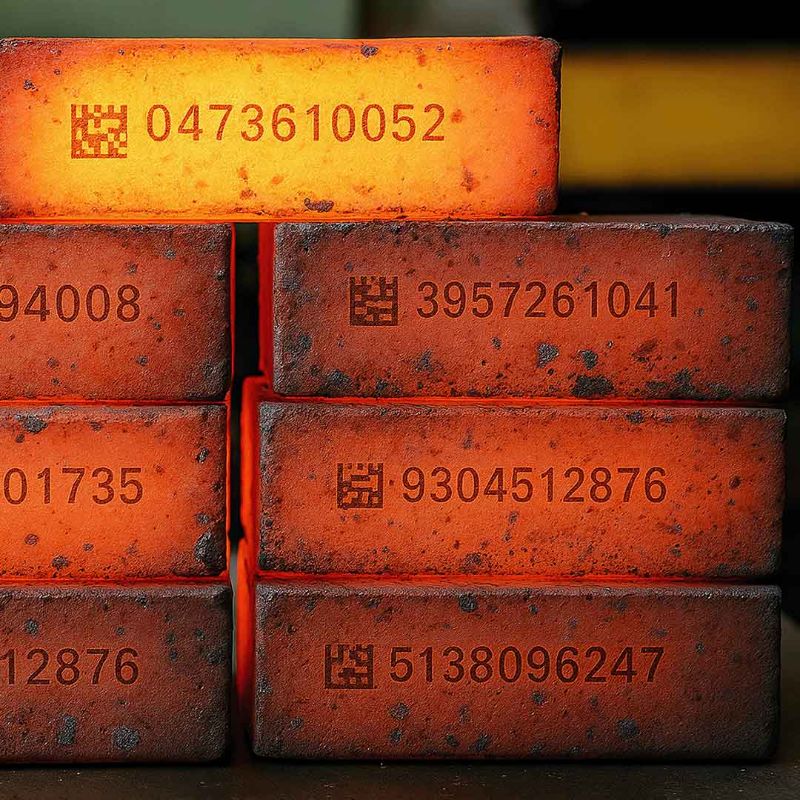

A laser marking machine is an industrial system that focuses a high-energy laser beam onto a material surface to create permanent, readable, and high-contrast markings. These machines are designed to meet the needs of mass production facilities for product identification, traceability, and brand visibility.

Working Principle

Laser marking machines operate using galvo scanning mirrors that direct the laser beam. The logo, barcode, or text designed on a computer is transferred to the laser system. The laser processes this data onto the surface within milliseconds, achieving different depths and color contrasts depending on the material type.

Laser Technologies Used

Fiber Laser

Provides the highest performance on metal surfaces. Thanks to its 1064 nm wavelength, it enables sharp and clear marking on stainless steel, aluminum, brass, and titanium.

CO₂ Laser

Used on organic materials such as wood, glass, leather, plastic, and paper. It delivers excellent results especially in packaging and decorative product applications.

UV Laser

Since it has low thermal impact, it enables high-resolution marking on sensitive materials such as plastic, silicon, and glass.

Advantages of Laser Marking Machines

High Speed and Efficiency

Thanks to galvo-based laser systems, hundreds of products can be marked within seconds. This provides high efficiency in mass production lines.

Contactless and Wear-Free Process

Since the marking process requires no physical contact, no deformation occurs on the surface. This preserves product quality.

Low Operating Cost

Laser marking machines do not use ink, labels, or chemicals, resulting in very low maintenance and operating costs.

Long Service Life and Stable Performance

With solid-state laser architecture, they offer an average operating life of 100,000 hours. Even under intensive use, there is no performance loss.

Application Areas

Automotive Industry

Chassis numbers, engine parts, sensors, and control panels are permanently marked with laser marking machines.

Electronics Industry

Laser marking is performed with high precision on small electronic components, circuit boards, and microchips.

Medical Devices

Surgical instruments and implants made from biocompatible materials are marked using laser marking that is resistant to sterilization processes.

Packaging and Food Industry

Expiry dates, production codes, and batch numbers can be marked directly onto packaging. Since no ink is used, it is a hygienic solution.

Highlighted Features of Laser Marking Machines

High Resolution

Barcodes, QR codes, or serial numbers can be processed at a precision of 0.001 mm.

Dynamic Data Processing

Data processing can be performed for each product by integrating with ERP or MES systems.

Automatic Focusing and Image Processing

Smart sensors automatically detect surface height. This allows error-free marking of parts with varying heights.

Inline Integration

Inline laser marking systems can be integrated into production lines, allowing marking without interrupting the product flow.

Technical Parameters

Power Range

Energy levels suitable for different material types are provided with 20W, 30W, 50W, and 100W models.

Marking Area

Standard areas range from 110x110 mm to 300x300 mm. X-Y axis systems are preferred for larger surfaces.

Cooling System

Air-cooled or water-cooled models maintain temperature stability even during long-term use.

Software Compatibility

Laser marking software compatible with CAD/CAM programs can perform variable data processing and automatic code generation.

Selection Criteria for Laser Marking Machines

Material Type

Fiber lasers should be preferred for metal surfaces, CO₂ lasers for organic surfaces, and UV laser machines for sensitive surfaces.

Production Volume

Compact desktop models are suitable for low-volume production; industrial inline machines are suitable for high-volume production.

Integration Requirements

Machines compatible with PLC, robotic arm, or conveyor integration should be selected.

Service and Support

It is important to work with manufacturers that provide technical service, spare part support, and software updates for long-term use.

Conclusion

The laser marking machine is the most efficient identification tool in industrial production, offering speed, accuracy, and permanence. Venox laser marking solutions guarantee high quality and traceability by integrating into production lines of all scales.