Laser Marking Machines for Plastic, Composite and Coated Surfaces: Material-Based Strategies

Selecting the Right Source: The Role of CO₂, UV and Fiber

For laser marking machines (or systems) on plastic, composite and coated surfaces, the choice of laser source depends on the optical/thermal properties of the surface. CO₂ enables surface etching/color change on organic and painted surfaces; UV provides micro and precise marking with low thermal impact (cold marking); Fiber is used in special cases such as filler-loaded polymers and coating removal (paint/epoxy ablation).

Material Behavior: Foaming, Darkening and Ablation

In polymers, contrast is mostly achieved through foaming (microbubbles), carbonization (darkening), or color change (dye/pigment interaction). On coated/organic surfaces, controlled ablation (paint removal) is prioritized.

Engineering Plastics: ABS, PC, PA, PBT, PEI, PPSU etc.

- Recommendation: Low-thermal-impact marking with UV lasers; high contrast on PC/ABS blends.

- Note: Additives (TiO₂, carbon black) increase absorption and narrow the parameter window.

- Applications: Electronics, automotive interior trim, medical disposables (UDI).

PP, PE, HDPE and Low-Absorption Polymers

- Recommendation: Marking with UV or surface modification with CO₂; additives (masterbatch) may be required.

- Foaming: CO₂ foaming provides light contrast; homogeneous fill/hatch is critical.

- Applications: Packaging, caps, bottles, industrial containers.

Coated/Painted Surfaces: Paint/Epoxy Removal (Ablation)

- Recommendation: Layer-by-layer ablation using CO₂ or Fiber; the base material must not be damaged.

- Parameters: Low pulse energy + multiple passes; spot overlap optimized to prevent side burning.

- Applications: White goods panels, automotive trim, serial/icon marking, mask removal.

Composites (CF/Glass-Filled, CFRP, GFRP)

- Recommendation: Contrast on carbon-filled surfaces using Fiber laser; minimize local damage using UV.

- Risk: Scatter depending on fiber direction; hatch direction and energy density must be selected carefully.

- Applications: Automotive/aerospace parts, industrial housings.

Optics and Lens Selection: Field–Spot Size Balance

F-Theta lens determines the marking field (e.g. 100×100–300×300 mm) and spot size. A small spot is ideal for fine text/symbols; larger fields with multiple pass strategies are suitable for coating ablation and large logos.

Hatch/Fill Strategies: Contrast and Edge Quality

- Multiple passes: Alternating hatch at 0°/45°/90° for homogeneous filling.

- Line spacing: Narrow spacing on plastics yields cleaner edges; excess energy can cause foaming/melting.

- Pulse parameters: Short pulses—low HAZ (UV); heat input must be controlled in CO₂.

Color and Pigment Interactions

Darkening works better on light-colored polymers, while lightening/foaming is more effective on dark surfaces. Additive/masterbatch compatibility must be tested. When needed, laser marking additives can be used to increase contrast.

Vision Verification and Code Quality

- 2D/1D Codes: Quality grading per ISO/IEC 15415/15416; angled lighting for surface reflections.

- OCR/OCV: Text and logo integrity; artifact control from fill/hatch.

- Color variance: Threshold/contrast adjustment for material lot changes.

Safety and Filtration

HEPA + activated carbon filtration is essential for organic fumes/particles. Class 1 enclosure, door interlocks and fume extraction are fundamental for operator safety and compliance.

TCO and Maintenance Perspective

- Filter life: High in coating ablation; replacement planning is needed.

- Lens cleaning: Polymer vapors may leave residue on optical glass; periodic cleaning required.

- Parameter recipes: Version-controlled recipes must be stored per material/color/coating.

Sample Approval and Commissioning Checklist

- Material/color/additive data sheet and sample set

- Contrast target (ΔL*, visual/vision grade) and tolerances

- Hatch/parameter recipe, optics/lens and focal distance

- Filtration capacity and maintenance intervals

- ISO/IEC quality grade, OCR/OCV threshold and reject/sort logic

FAQ: “Makinaları” or “Makineleri”?

In technical writing, “makineleri” is common; however, in SEO the phrase “laser marking makinaları” also has search volume. It is recommended to include both naturally within the content.

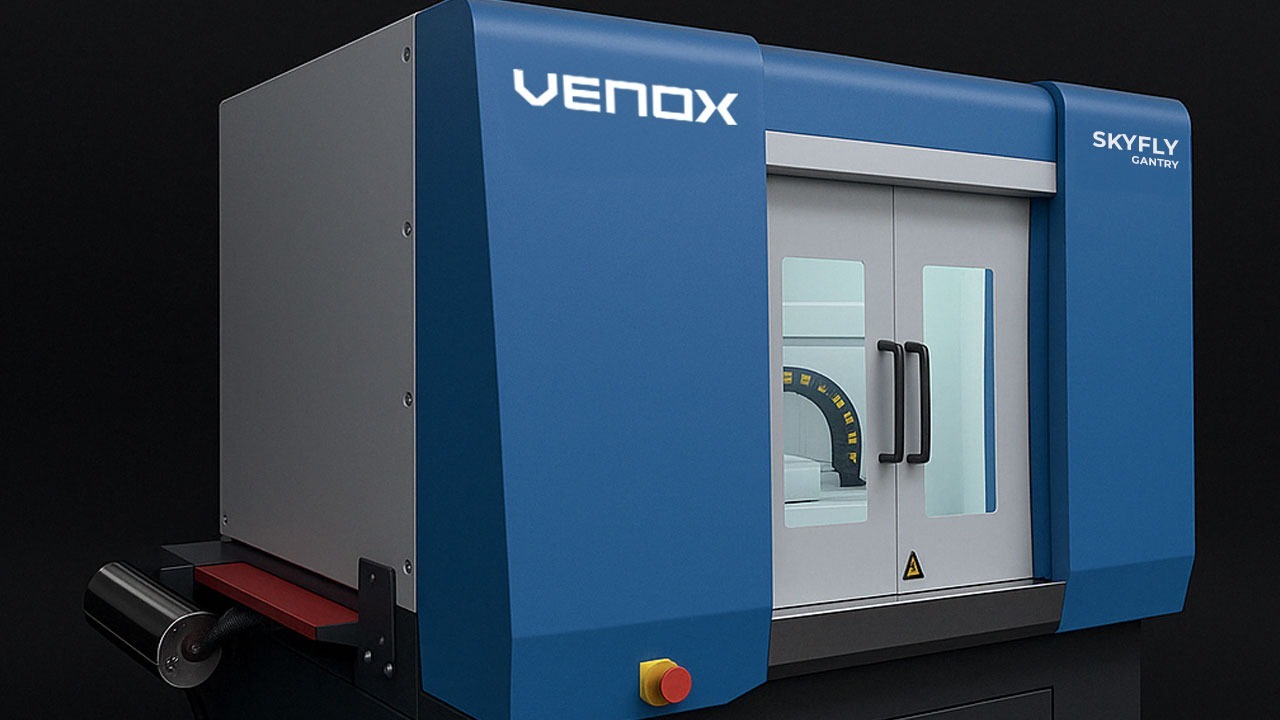

Material-Based Solutions with Venox

We provide turnkey UV/CO₂/Fiber configurations with vision verification and inline integration for plastic, composite and coated surfaces. Explore our products: Laser Marking Machines.