Traceability with Laser: The Technology Shaping the Future of Industry

In today’s production and logistics sectors, key topics such as product tracking, quality control, and counterfeiting prevention play a critical role in enhancing the competitiveness of businesses. In this context, the high precision and durability offered by laser technology have become an indispensable part of traceability systems. With its innovative solutions in laser and marking, Venox Teknoloji stands out in the sector while providing its customers with reliable and sustainable product traceability. You can find more detailed information about Venox Teknoloji’s Firefly Integrated solution here.

What is Laser Marking?

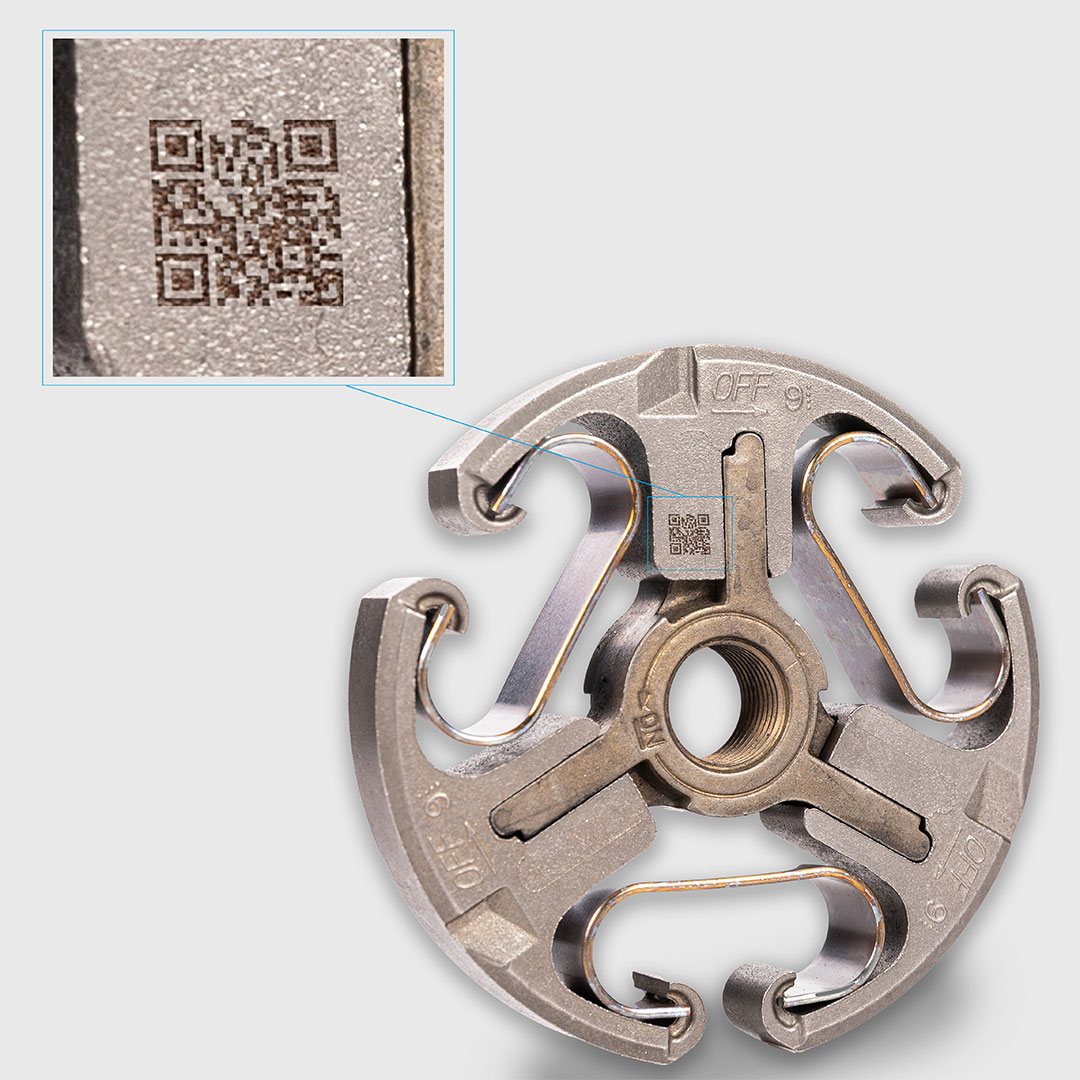

Laser marking is a technology used in industrial applications to create permanent and high-quality markings on materials. With this technology, serial numbers, barcodes, QR codes, or custom patterns can be generated on products. Compared to traditional methods, laser marking offers faster, more precise, and longer-lasting results. During the process, the laser beam focuses on the surface to be marked, making minimal changes to the material’s structure. This ensures the permanence and readability of the marking.

The Importance of Traceability for Businesses

Traceability refers to the ability to record and track the history of a product at every stage from production to the end consumer. In today’s competitive environment, traceability systems are crucial for ensuring product quality and safety, while also enhancing transparency throughout the supply chain. Through detailed product tracking, businesses can:

- Quality Control: Identify the source of product defects and improve product quality.

- Counterfeit Prevention: Prevent counterfeit products from entering the market by verifying product authenticity.

- Efficiency: Optimize production and logistics processes, saving time and costs.

- Regulatory Compliance: Ensure compliance with international standards and regulations, protecting brand reputation.

Advantages of Laser Technology in Traceability

The main reasons for preferring laser-based traceability applications include:

- Highly Durable Marking: Laser marking leaves permanent traces on the product surface, ensuring the markings remain intact even under harsh environmental conditions.

- Precision and Detail: Laser technology can achieve micro-level detail, enabling high-resolution markings on even small surfaces.

- Fast Production Process: With its automatic and rapid operation, it eliminates bottlenecks in the production line.

- Cost-Effective Solutions: With its long lifespan and maintenance-free structure, it provides long-term cost advantages for businesses.

- Compatibility with Various Materials: Can be effectively used on a wide range of materials including metal, plastic, and glass.

Venox Teknoloji’s Solutions

Venox Teknoloji plays a pioneering role in the industry with its innovative solutions for laser-based traceability. The Firefly Integrated system developed by the company offers a fully integrated traceability solution for production processes, providing all the data and analytics that businesses need. With this system, products can be tracked and verified at every stage from production to distribution.

Venox Teknoloji’s approach goes beyond product marking by also supporting process management and data analysis. This enables customers to monitor not only product information but also all data from production and logistics processes in real time. This holistic solution enhances both operational efficiency and product safety to the highest level.

To learn more about Firefly Integrated, one of the company’s featured solutions, you can visit the official website of Venox Teknoloji.

Examples of Laser Marking Applications in Industry

The use of laser technology for traceability spans a wide range of industries. It has been successfully implemented in the following sectors in particular:

- Automotive Sector: Permanent marking of parts and components with serial numbers plays a critical role in quality control and warranty processes.

- Electronics and Telecommunications: High-resolution markings on small components ensure product authenticity and quality.

- Medical Products: Traceability of surgical tools and medical devices is vital for patient safety.

- Packaging and Logistics: Laser-marked barcodes and QR codes on packaging enhance tracking and efficiency in distribution processes.

Future Traceability Solutions

As technology advances rapidly, traceability systems are continuously evolving. Laser marking solutions integrated with the Internet of Things (IoT) and big data analytics have the potential to provide detailed information throughout the entire product lifecycle. Venox Teknoloji aims to offer future-proof, sustainable, and intelligent solutions by leveraging these innovative technologies.

Laser technology offers significant advantages in areas such as real-time data collection on the production line, automation of quality control processes, and increasing production efficiency—substantially boosting the competitiveness of businesses. The systems developed by Venox Teknoloji adapt to this dynamic structure, ensuring data security and process optimization at every stage.

Reliable Traceability with Venox Teknoloji

With its experience in laser marking and strong technological infrastructure, Venox Teknoloji not only offers high-quality product marking services, but also provides comprehensive traceability solutions that optimize business processes. The systems offered by the company record every detail of products, delivering reliable data at every step from production to distribution.

This holistic approach offers businesses significant advantages in both quality management and regulatory compliance. By closely following evolving technology trends, Venox Teknoloji continues to offer flexible and scalable solutions tailored to customer needs. As a result, businesses can digitize their production processes and become more efficient and competitive thanks to the technological infrastructure provided by Venox Teknoloji.

Conclusion

Traceability with laser is a comprehensive technology that covers many critical areas in today’s industrial applications, such as quality control, counterfeit prevention, and operational efficiency. With its innovative solutions and integrated systems in this field, Venox Teknoloji provides its customers with long-term success and sustainable growth.

If you are looking for a smart and reliable solution for your business’s traceability needs, exploring the products and systems offered by Venox Teknoloji will be beneficial. For more information, visit the official website of Venox Teknoloji and the Firefly Integrated product page.

Choose Venox Teknoloji’s solutions to experience the benefits of future technologies and adapt your production processes to the demands of the digital age. The high precision, permanence, and speed offered by laser technology will increase your competitiveness, while the holistic structure of traceability systems will revolutionize process management. This way, you can maintain control and confidence at every step, managing all processes from production to distribution more effectively.

In conclusion, laser-based traceability is emerging as one of the key technologies for the future of industrial applications. Venox Teknoloji’s innovative approach and technological solutions make it easier for businesses to adapt to this transformation, opening the doors to competitiveness and sustainable success. Get ready to embrace the technologies of the future—experience the difference in traceability with Venox Teknoloji!

This blog post highlights Venox Teknoloji’s laser marking and traceability solutions in detail, shedding light on current industry trends and technological developments. Through the provided links, you can learn more and determine the most suitable solutions for your business needs.