Inline Laser Marking: Fast and Uninterrupted Marking on Mass Production Lines

What Is Inline Laser Marking?

Definition

Inline laser marking is an advanced laser technology that enables marking products in motion without stopping on production lines. Integrated into the automation infrastructure, this system allows high-speed and continuous marking.

How Does It Work?

As the product passes on the conveyor belt, it is detected by a sensor and the laser beam instantly focuses on the product surface. Thus, serial number, barcode, QR code, logo, or production date is permanently applied to the surface. All of this occurs without interrupting the product flow.

Advantages of Inline Laser Marking

Uninterrupted Production

Marking can be performed without stopping the production line. This feature provides time savings in high-volume production lines and maximum efficiency.

High Readability

Codes, text, and symbols produced by laser marking are resistant to wear, chemicals, and heat. They can be accurately read by barcode scanners for a long time.

Eco-Friendly Solution

Since no ink, solvent, or labels are used, it does not harm the environment. It also eliminates maintenance and consumable costs.

ERP and MES Integration

Inline laser marking systems can operate in sync with production management systems. In this way, product-based data can be marked automatically.

Use Cases

Automotive Industry

Engine parts, chassis components, sensors, and electronic modules are made traceable with laser marking.

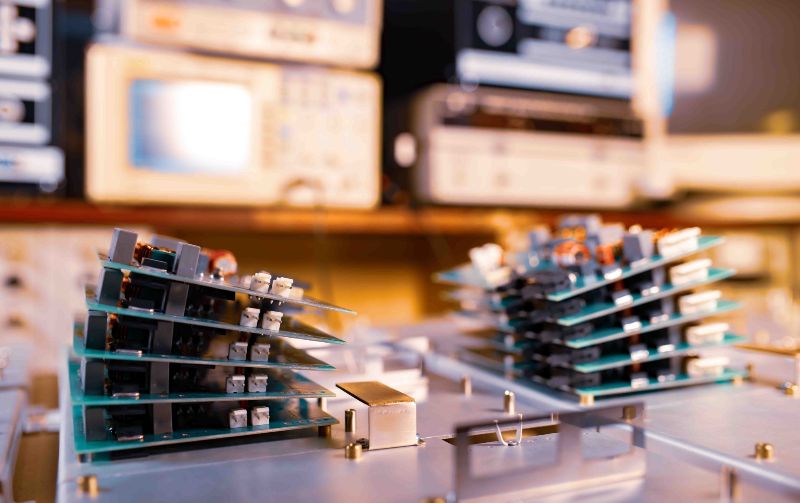

Electronics Production Lines

Fast and precise marking is provided on circuit boards, connectors, micro components, and metal tags.

Food and Beverage Packaging Lines

Information such as expiration date, batch number, and barcode is marked directly onto the packaging surface. This process is much more hygienic than inkjet printing systems.

Medical Production Lines

Permanent marking can be applied to sterile products such as syringes, medicine packaging, and surgical instruments. These marks remain visible even after sterilization.

Technological Features

Dynamic Focusing

Even if the product surface has varying heights, the laser is directed to the correct point with automatic focusing sensors. This ensures sharp and consistent marking.

Galvo Scanning System

Thanks to galvo mirrors, the laser beam can scan at speeds up to 7000 mm per second. This system provides maximum speed on production lines.

Camera-Assisted Verification

After marking, an integrated camera system checks the accuracy of the codes. Incorrectly marked products can be automatically rejected.

Automation Compatibility

Works fully compatible with PLC, SCADA, and robotic systems. Venox laser marking systems support this integration as standard.

Structure of an Inline Laser Marking System

1. Laser Unit

The fiber or CO₂ laser source is selected according to the type of material to be processed. Laser power is typically between 20W and 100W.

2. Conveyor Belt

The production line on which products move at a defined speed. Working in integration with sensors, it automatically sets the laser marking positions.

3. Control Unit

The computer system that receives marking data, manages laser parameters, and supervises the production process. Dynamic data processing can be performed.

4. Imaging and Quality Control System

After marking, it performs optical scanning to analyze code accuracy and readability.

Types of Inline Laser Marking

Fiber Laser Marking Lines

Used for marking metal parts. Provides high speed and deep marking.

CO₂ Laser Marking Lines

Ideal for packaging, plastics, paper, and organic materials.

UV Laser Marking Lines

Used for heat-sensitive products, especially medical materials and glass surfaces, for precise applications.

Machine Selection Criteria

Production Speed

The laser’s scanning speed should be adjusted according to the product flow on the line. For production lines of 200–600 parts per minute, high-speed systems are preferred.

Material Type

Fiber for metal, CO₂ for plastic, and UV laser machines for glass or silicon are recommended.

Data Management

If product-based marking is performed, ERP and database connectivity should be supported.

Integration Support

Venox industrial laser machines provide full integration with robotic arms and production lines, contributing to smart manufacturing processes.

Conclusion

Inline laser marking is an innovative technology that provides speed, accuracy, and continuity for mass-production manufacturers. Performing marking without pauses on the production line creates advantages in both time and cost. With Venox’s advanced laser systems, achieving permanent, readable, and aesthetic marking on production lines is now much easier.