Material-Based Applications and Best Results in Laser Marking Machines

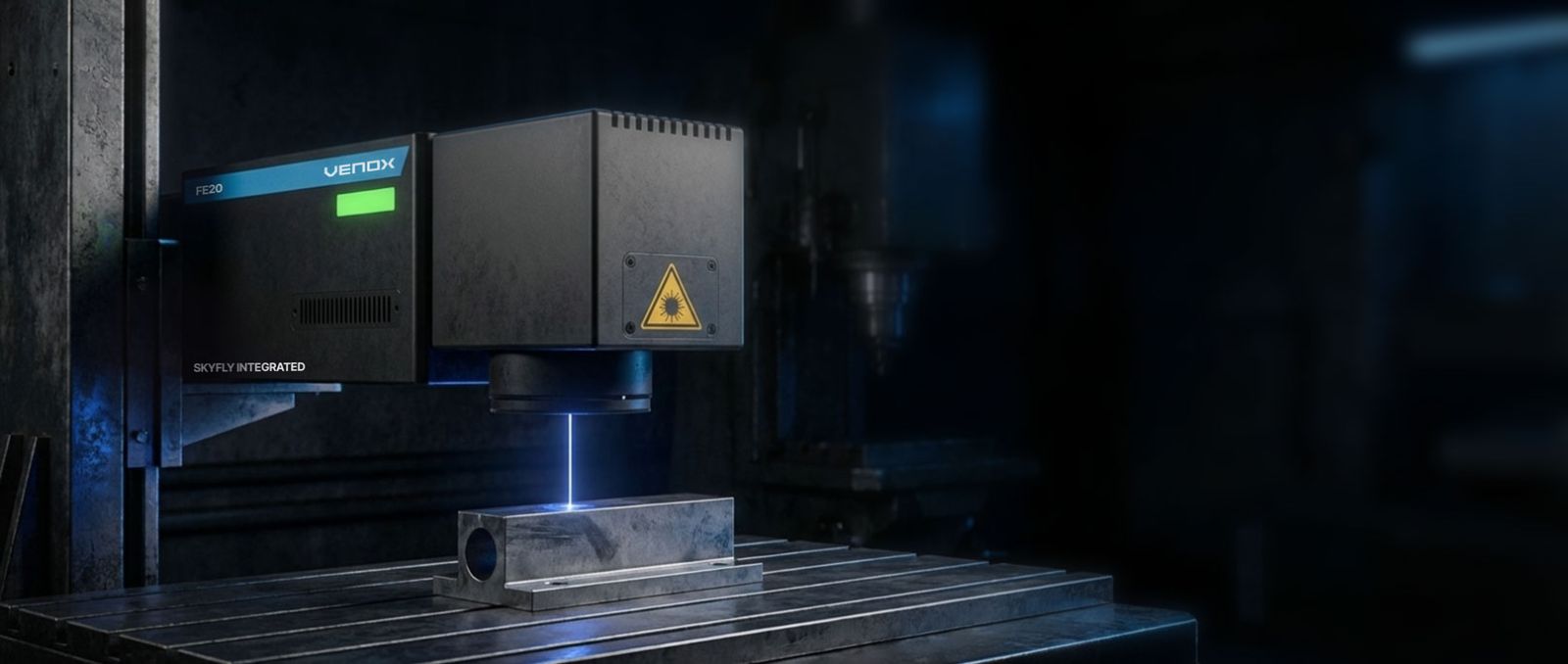

The success of laser marking technology largely depends on the correct management of the material–laser interaction. Each material requires different wavelength, power, and speed parameters. In this content, we discuss best-practice approaches for laser marking on common industrial materials. For Venox solutions: Laser Marking Machines.

Laser Marking Applications on Metals

Metals are the most commonly processed material group in laser marking technology. Fiber laser systems deliver high performance in metal applications in terms of speed, contrast, and permanence.

Stainless steel marking

Laser marking on stainless steel can be applied using oxidation, color change, or deep engraving methods. It is widely used in the food, medical, and automotive industries.

Aluminum and alloys

Laser marking on anodized or raw aluminum surfaces produces high-contrast results. Fast and clear marking is possible in mass production.

Cast and hard metals

Cast parts and hard alloys can be permanently marked through deep laser engraving. This method is resistant to harsh operating conditions.

Coated metal surfaces

On painted or coated metals, the laser selectively removes the coating, creating a clear contrast on the underlying surface.

Laser Marking on Non-Metal Materials

Laser marking on non-metal surfaces is generally carried out using CO₂ or UV laser technologies. Thermal effect control plays a critical role in these applications.

Plastic marking

Laser marking on ABS, PP, PE, and engineered plastics is achieved through color change or surface structuring. UV lasers are preferred for sensitive plastics.

Glass and ceramic surfaces

Laser marking on glass creates a matte appearance by forming micro-cracks. It is used for bottles, laboratory equipment, and decorative applications.

Wood and organic materials

CO₂ laser systems provide aesthetic and controlled marking on organic materials such as wood, leather, and cardboard.

Rubber and elastomers

Laser marking on rubber surfaces offers a clean and contactless solution for printing molds, seals, and industrial components.

Composite and special materials

Laser marking on composite materials must be performed in a controlled and superficial manner without damaging the layered structure. Correct parameter selection is critical.

Material-based laser marking solutions with Venox

Venox aims for optimal results in laser marking projects through material-based testing and application analysis. To determine the solution specific to your application, you can review the Venox laser marking machines page.

Selecting the appropriate laser technology for the material is a determining factor in terms of quality, speed, and surface integrity.

To achieve the best laser marking results for your materials, you can conduct an application-based evaluation with