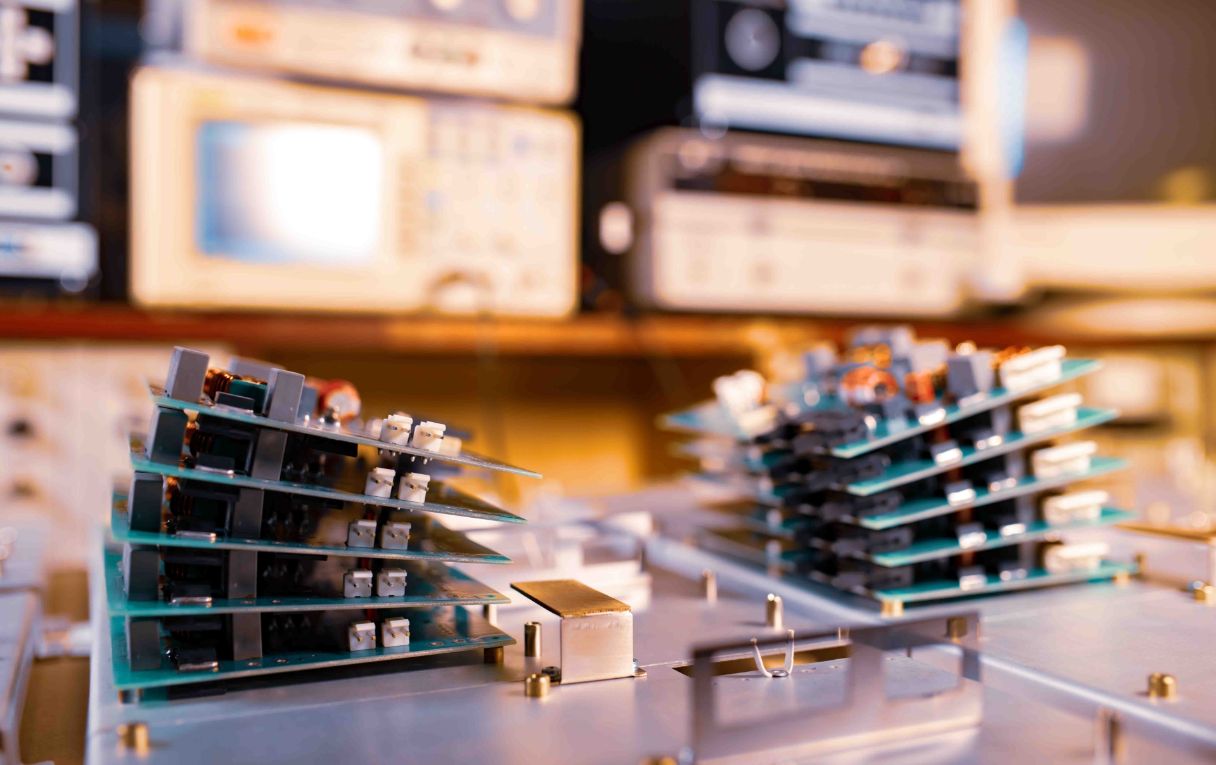

Our Laser Marking Machines Service Solutions

Venox Teknoloji offers an end-to-end service ecosystem for your laser marking machines: fast fault management supported by remote diagnostics, operator competency strengthened through training and process consultancy, and a high first-visit resolution rate ensured by spare parts and logistics planning. Our goal is to keep your line operating with minimum downtime, without compromising safety or quality. Even in multi-shift production environments, we synchronize service windows with your production plan to minimize losses and standardize repeatable marking quality.

Field & Remote Service Scope

Our service scope includes installation-commissioning, periodic inspections, fault interventions, process validation tests, and safety compliance audits. For fiber, CO2, and UV laser sources, we separately examine the optical path, scanner dynamics, power stability, and field uniformity. When required, secure-tunnel remote access is used for log analysis, parameter set review, and temporary improvements; and since the correct parts are reserved before arriving onsite, the “first visit resolution” rate increases significantly.

Fault Management and SLA

Our fault management workflow includes the steps: call intake > remote preliminary diagnosis > spare parts reservation > on-site intervention > test marking > reporting. In our SLA model, call response, remote diagnosis start time, on-site arrival, and resolution targets are clearly defined and shared transparently through monthly/quarterly reports. This way, you can view service performance and operational goals on the same dashboard.

Installation and Commissioning

For new lines or machines, environmental conditions (dust load, temperature, vibration), extraction system performance, and electrical-grounding infrastructure are verified. Optical path alignment, focus reference, and field uniformity are calibrated; initial process validation is performed using reference markings. Operators receive training on basic maintenance, safe operation, and parameter literacy.

Spare Parts and Logistics

The use of original spare parts is essential for lens coating compatibility, wavelength matching, and scanner dynamics. We recommend stocking policies for lenses, protective glass, scanner windows, PSUs, fans/filters, and specific cable sets; for critical lines, consignment and “backup set” applications enable a return to production within hours.

Advantages of the Venox Service ModelStandardized checklists, measurable SLAs, remote diagnosis before field visits, and planned logistics—all together mean shorter downtime and higher repeatable quality. By reporting data related to your process, we provide a technical basis for management decisions.

Safety and Compliance

Laser class requirements including door switches, interlock chains, emergency stop circuits, and safety shielding are verified during every visit. Occupational health and safety standards and CE/marking compliance checks are reported, and corrective action plans are prepared for any nonconformities.

Training and Process Improvement

Service works in full integration with training and process consultancy. We deliver short modules to enhance operator skills in focusing, test grid interpretation, hatch strategy selection, and material-based parameter management. Related pages: Teknik Servis, Eğitim, Uygulama Danışmanlığı.

Service Workflow: Request > Diagnosis > Solution

When your request is received, we begin preliminary analysis the same day. Based on log and parameter inspection, a temporary solution is shared; when the visit is scheduled, required parts are reserved. After intervention, quality is verified through test marking, field uniformity checks, and contrast measurements; the report and recommendations are then delivered.

Contract Options

We offer flexible service contracts depending on your operational criticality: standard package (annual visit + discounted hourly rate), advanced package (short SLA + remote monitoring), and 24/7 package (for critical lines). All packages include reporting and an annual process evaluation session.

Industry Applications and Reference Scenarios

High-volume serial production in automotive and white goods, traceability and clean marking in medical applications, precise geometry and low thermal impact expectations in electronics—each requires specific parameter and maintenance strategies. With the right approach, we help you reduce quality costs and keep return and rework rates under control.

Summary in a Single List

- Fast remote diagnostics + correct spare parts = first-visit resolution.

- Safe operation ensured through safety and compliance checks.

- Sustainable quality through integrated training and consultancy.

- Predictable costs with flexible SLAs and contract options.

- Transparent performance with reportable metrics for management.