Safety, Occupational Health, and Legal Compliance Guide for Laser Marking Machines

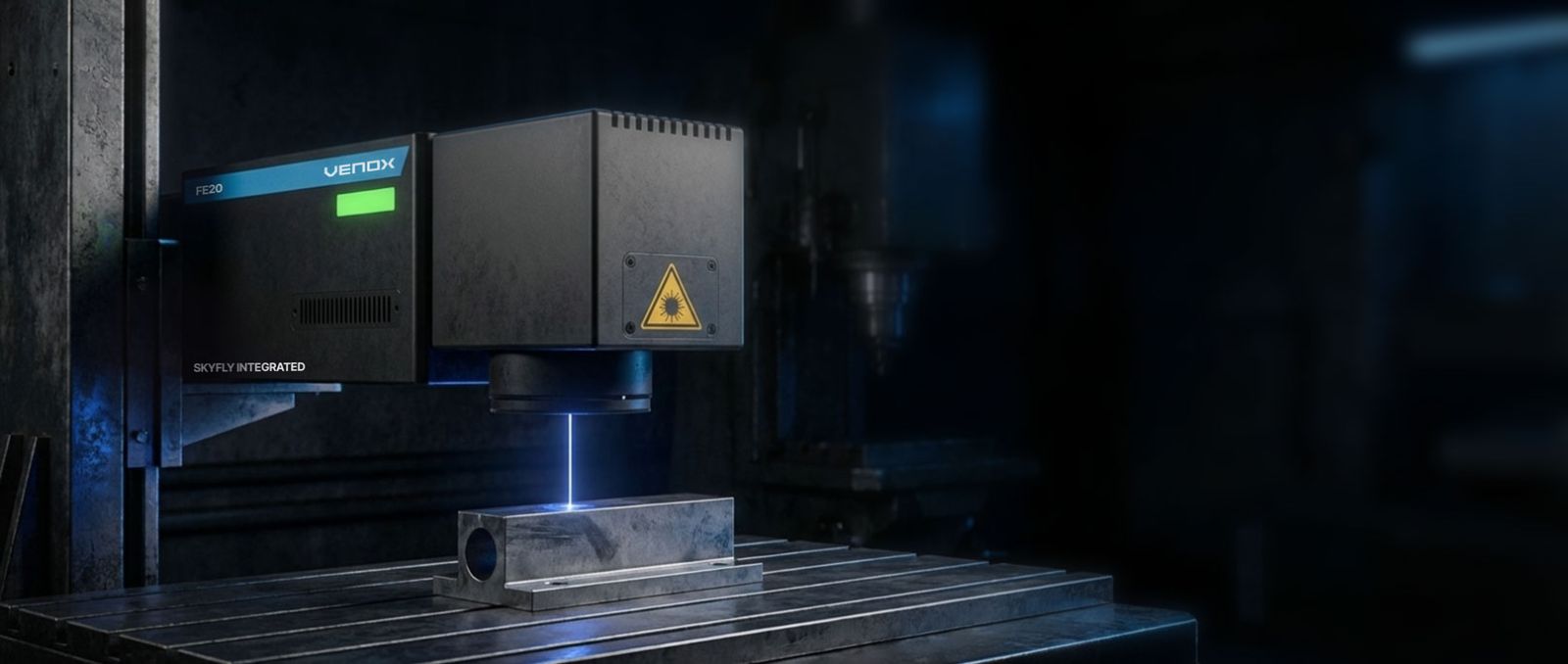

Laser marking machines are industrial systems that operate with high energy. Therefore, occupational health and safety (OHS) is not merely a preference, but a legal and operational requirement. Proper safety measures protect employees, ensure production continuity, and guarantee full compliance with regulations. For Venox solutions: Laser Marking Machines.

Basic Safety Risks in Laser Marking Systems

In laser marking applications, risks may arise from the laser beam, fumes and gases, electrical components, and mechanical movements. Proper analysis of these risks forms the foundation of a safe working environment.

Risk of exposure to the laser beam

Industrial lasers are generally in the Class 4 category. Direct or reflected laser radiation can cause serious damage to the eyes and skin. Therefore, complete isolation of the laser beam is critical.

Fume, gas, and particulate generation

Fumes generated during marking may contain toxic components depending on the material. Effective fume extraction and filtration systems minimize respiratory risks.

Electrical and mechanical hazards

High-voltage components and moving parts can pose risks during maintenance and service. Lockout/tagout (LOTO) procedures are important at this stage.

Fire and thermal risks

Laser marking on flammable materials can introduce a fire risk. Proper parameter settings and environmental control are essential.

Occupational Health, Safety Measures, and Regulatory Compliance

Safe use of laser marking systems should be addressed together with technical equipment, organizational measures, and training. This approach ensures that legal obligations are fully met.

Safety enclosure and interlock systems

Enclosed-cabin laser marking machines prevent laser radiation from escaping into the surrounding environment. Interlock structures that stop the system when the door is opened are mandatory.

Personal protective equipment (PPE)

In open systems or during maintenance, laser protective eyewear with the appropriate wavelength rating must be used. Gloves and other protective equipment are determined according to the risk assessment.

Risk assessment and documentation

Detailed risk assessments should be conducted for laser marking stations and updated regularly. These assessments serve as key references during audits.

Operator training and authorization

Personnel who will operate laser marking machines must be trained in laser safety, emergency situations, and basic maintenance. Unauthorized use increases risks.

Compliance with national and international standards

CE marking, the Machinery Safety Directive, and relevant laser safety standards are the main references for laser marking systems. Compliance with these standards reduces the company’s legal liabilities.

Safe laser marking solutions with Venox

Venox designs laser marking machines in accordance with occupational health and safety requirements. For safe, compliant, and sustainable solutions: you can review the Venox laser marking machines page.

Safe laser marking is possible with the right technical measures + training + regulatory compliance.

To implement laser marking applications in your facility safely and in compliance with laws, you can benefit from Venox expert support.