Glass laser cutting technology is a modern manufacturing method that enables high-precision cutting, shaping, and processing of glass materials. It is widely used, particularly in industrial production, architectural decoration, automotive, packaging, and art fields. However, making the right choice between glass laser cutting machines is critical for both production quality and operational efficiency. Therefore, before making an investment, many technical and operational factors must be carefully considered.

1. Technical Specifications and Performance Criteria

The first step in selecting a glass laser cutting machine is to determine whether its technical specifications meet your production needs. Factors such as cutting speed, power capacity, laser type, and processing area directly affect production quality. The laser's power must be sufficient for the thickness of the glass; it should also have precise modes to reduce the risk of cracking in very thin glass. In this regard, understanding the differences between laser cutting systems is crucial. Additionally, the machine's software support and the ability to customize cutting parameters are also key considerations.

2. Operational and Maintenance Costs

Glass laser cutting machines are high-precision devices that require regular maintenance and calibration. The availability of spare parts, ease of maintenance, and energy consumption levels determine long-term operational costs. In this context, getting support from manufacturers offering custom solutions provides significant advantages during maintenance. Furthermore, machines with low energy consumption are both environmentally friendly and reduce operational costs.

Laser Power and Optical Quality

Laser power is one of the factors that directly affects the cutting quality of glass. Very high power can increase the risk of thermal stress and cracking, especially in thin glass. Therefore, the quality of optical components and the precision of laser beam focusing play a critical role in machine selection. Laser marking systems with advanced optical technologies can also be integrated into glass cutting machines.

Cutting Area and Workpiece Size

The machine's working area should be determined based on the production capacity. Models with large table areas are required for processing large glass panels, while compact machines are sufficient for small-scale decorative products. The precision of the machine's table movement is crucial, especially for tasks requiring high detail, such as fine patterns and text processing.

Cooling System and Heat Control

Since glass material is heat-sensitive, controlling the thermal stress generated during cutting is essential. Therefore, the efficient operation of the machine's cooling system is of utmost importance. Closed-loop water cooling systems provide both energy efficiency and long-term stable performance.

Automation and Software Integration

Modern glass laser cutting machines can automate the production process by integrating with CAD/CAM software. This allows complex designs to be cut in a short time and minimizes error rates. Features such as automatic focusing and recognition of cutting parameters reduce the operator's workload. Similar technologies are used in laser marking machines.

Safety Standards

Safety is a priority for both the operator and the production environment in laser machines. The machine must have international safety certifications, and the laser beam should be isolated with protective panels. Features such as emergency stop buttons are also essential. Additionally, an effective aspiration system should be in place to filter any glass dust generated during laser cutting.

Energy Efficiency

Energy consumption is a significant cost, especially for businesses that engage in continuous production. Fiber laser technologies, which offer higher efficiency, consume less energy compared to CO₂ lasers. Moreover, machines that consume minimal energy in standby mode should be preferred.

Brand and Manufacturer Warranty

When purchasing a machine, the post-sales support and warranty period provided by the manufacturer should be evaluated. Manufacturers with a strong service network in Turkey and globally offer uninterrupted support in case of potential malfunctions. Therefore, working with expert companies in laser cutting and marking machines offers great advantages.

Test and Sample Cutting Service

Before making an investment, conducting sample cutting with the selected machine is critical to see whether it meets production needs. Sample tests provide an objective opportunity to evaluate both cutting quality and speed.

Spare Parts and Supply Availability

For the continuity of maintenance, spare parts for laser cutting machines must be easily obtainable. The availability of critical components, such as optical lenses, laser tubes, and cooling systems, from the manufacturer’s stock is important. Therefore, brands with local service and supply support should be preferred.

Operator Training and Ease of Use

The personnel using the machine must receive adequate training, which is important for both job safety and efficient production. Some manufacturers provide comprehensive training programs upon machine delivery. Additionally, machines with user-friendly interfaces speed up the production process and reduce errors.

Environmentally Friendly Production

Environmental sustainability is an important criterion in modern production processes. Glass laser cutting machines are expected to have low energy consumption, provide recyclable waste management, and minimize harmful gas emissions.

Price and Return on Investment

The machine price should not be the sole selection criterion. Choosing a model that increases the production capacity, minimizes defective production, and ensures long-lasting usage shortens the return on investment period. Therefore, the price-performance balance should be carefully analyzed.

Service and Technical Support Speed

Fast resolution of any malfunctions during production is essential for continuous operation. Therefore, the technical support time and the experience of the service team should be considered when selecting a machine.

References and User Experiences

Before purchasing the machine, it is beneficial to review the comments of businesses that have used the same model. User experiences provide insights into practical advantages and disadvantages that are not covered in technical data.

Technological Upgradability

Since industrial technologies are continuously developing, it is important for the selected machine to be upgradable in terms of both software and hardware. Machines with a modular structure can be made compatible with new technologies.

Production Flexibility

Being able to process glass products of different thicknesses, sizes, and forms provides production flexibility. Therefore, machines with wide material compatibility increase the long-term value of the investment.

Conclusion

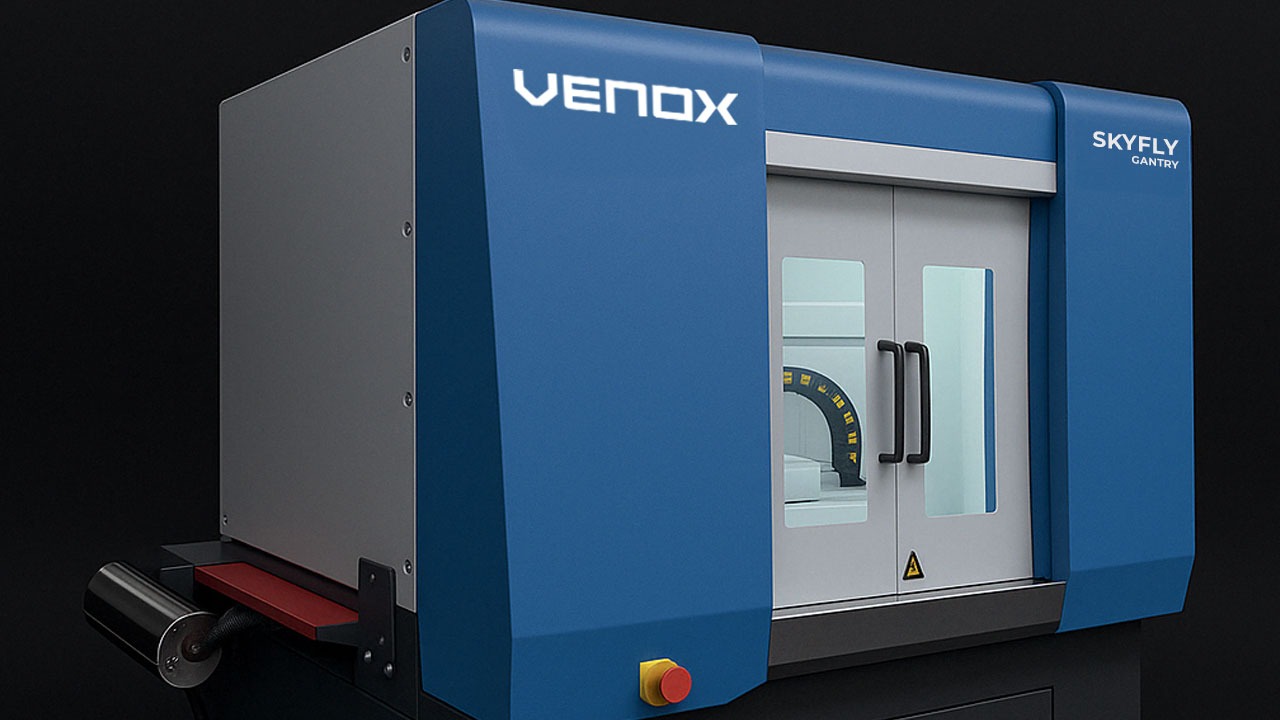

Choosing a glass laser cutting machine should not only be based on technical specifications but also on operational needs, ease of maintenance, energy efficiency, and manufacturer support. The right machine improves production quality while reducing operational costs. The laser cutting systems and laser marking solutions offered by Venox Technology enhance businesses' competitive power with high precision and long-lasting performance.