Venox Teknoloji International Laser Marking After-Sales Maintenance

Venox Teknoloji provides integrated after-sales maintenance for your laser marking machines in global installations, ensuring uninterrupted and safe operation through preventive plans, remote diagnostics, original spare parts, and on-site validation tests. Maintenance schedules are created according to local needs by considering different climate and grid conditions, production standards, and traceability requirements.

Global Preventive Maintenance Model

Our maintenance approach is based on standardized checklists in which optical, mechanical, and software layers are validated separately. Maintenance frequency and scope are determined by analyzing regional dust load, temperature-humidity profile, and shift patterns. This reduces unplanned downtime and keeps marking quality stable between calibrations.

- Optical path: F-Theta, protective glass and scanner window cleaning + alignment references.

- Power/cooling: PSU fluctuation test, chiller flow-temperature verification, fan/filter replacement.

- Quality verification: field uniformity, spot size, contrast and geometry test grids.

- Safety: interlock chain, emergency stop, door switch and laser class checks.

- Software/communication: parameter set versioning, log inspection, ERP/MES integration check.

Remote Monitoring and SLA

In suitable installations, log and parameter analysis is performed through a secure tunnel, allowing issues to be isolated before an on-site visit is required. Our SLA model clarifies targets for call response, remote diagnostics start time, site arrival, and resolution. Monthly/quarterly reports transparently share performance indicators.

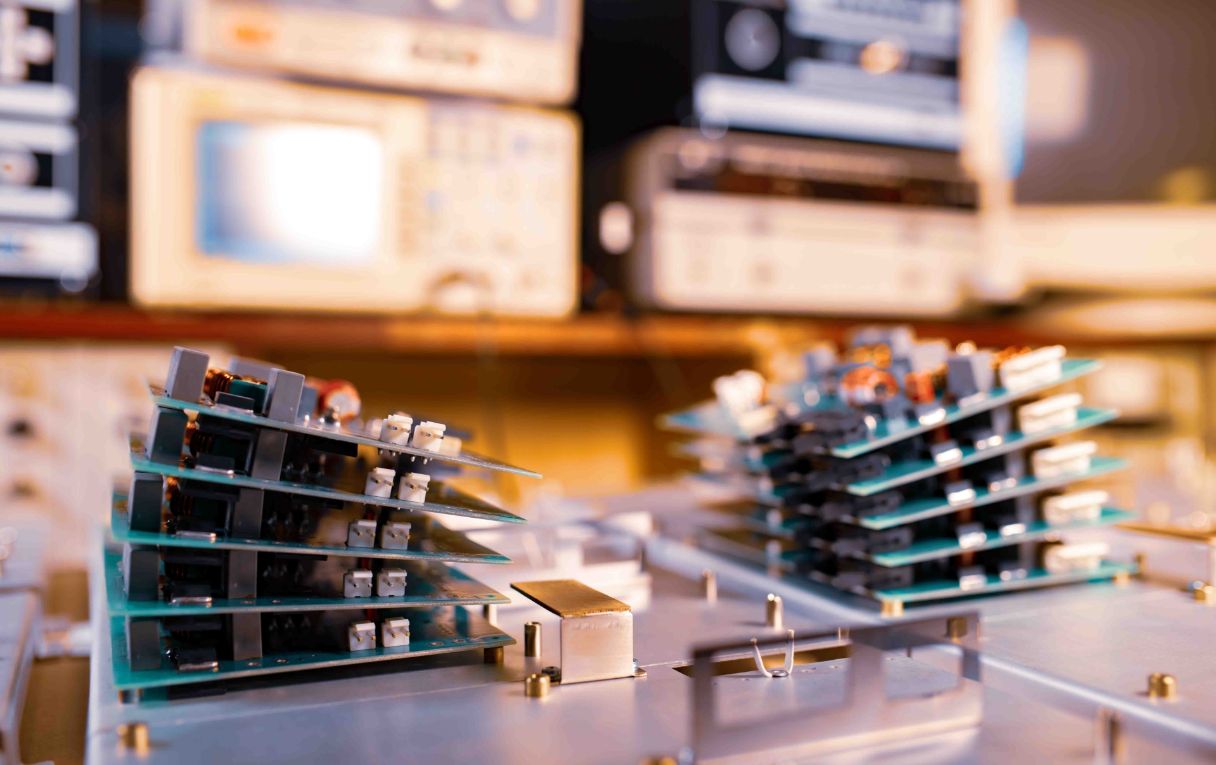

Spare Parts and Forward Stock

Forward stock and consignment options are provided for critical components (protective glass, scanner window, PSU, fan/filter, specific cable sets) on a country/region basis. This increases first-visit resolution rates and reduces shipping lead times.

Post-Installation Calibration

After international commissioning, focus, field uniformity and speed-power matching are verified on-site. Test markings are made on reference material; the report and recommendations are shared with your operations team.

Why Venox International Maintenance?Single supplier, single point of responsibility: equipment + commissioning + training + maintenance. Standardized procedures and an original spare parts policy ensure repeatable quality regardless of geography.

Training and Process Consultancy

Operator training and process improvement modules are integrated into maintenance programs. Thanks to focus practices, hatch strategies and parameter literacy, operator-induced quality fluctuations are minimized. Related pages: Teknik Servis, Eğitim, Uygulama Danışmanlığı.

Adaptation to Climate and Environmental Conditions

In regions with high humidity, dust, and temperature fluctuations, extraction placement, air-knife cleaning, and filter intervals are reconfigured. This slows down optical contamination trends and keeps calibration stable.

Process Flow: Request > Diagnosis > Intervention

After a service request, remote diagnostics begin, potential spare parts are reserved, and the site visit is scheduled. After intervention, test markings verify quality and a report is shared. The entire process is documented end-to-end.