Venox Teknoloji International Laser Marking Machines

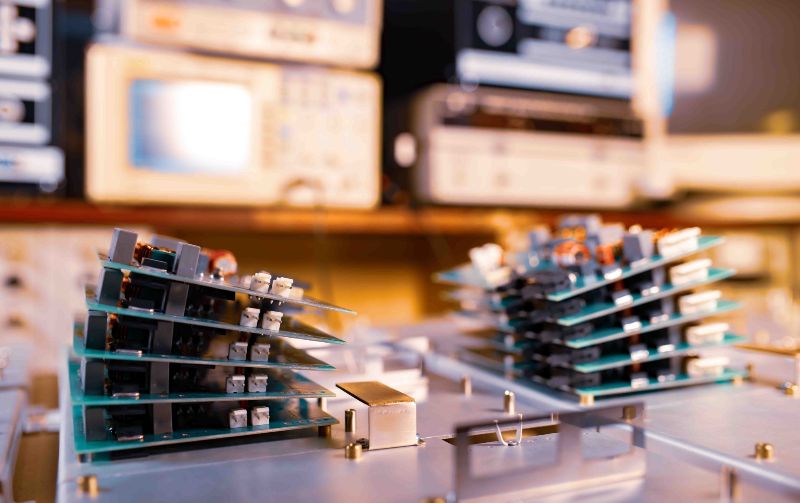

Venox Teknoloji offers laser marking machines for global markets with multi-voltage compatibility, industrial standardization and field-validated process sets. Our fiber, CO2 and UV configurations can be adapted to different material groups, climate conditions and production workflows. In international projects, we do more than supply equipment; we integrate installation, commissioning, training and technical service under the same structure.

Global Compliance and Certification

International regulations and application requirements are critical factors in machine selection and commissioning success. Venox addresses laser safety, EMC/EMI and industrial marking quality criteria throughout the project lifecycle; providing verification workflows and test grids for traceability (UID/Datamatrix/QR) applications.

- Multi-voltage/frequency compatibility (110–240 V, 50/60 Hz), with chiller/filter options suited to field conditions.

- Interlock chain, emergency stop and door switch validation for operator safety; class labeling.

- Traceability: verification procedures for code quality, contrast and geometric accuracy.

- Industrial communication: ERP/MES connections through digital I/O and network-based protocols.

Logistics, Customs and Commissioning

During project planning, we determine Incoterms, delivery/installation window and spare parts strategy together from the start. Shipping packaging, environmental conditions and infrastructure requirements of the installation site (grounding, extraction, climate control) directly affect commissioning success. The Venox team performs field homogeneity and focus validation during the first-day test markings, completing operator training and process validation in the same visit.

Model and Configuration Selection

For each application, we optimize wavelength, scan field, F-Theta lens combination, pulse frequency and hatch strategy based on the workpiece in the field. This approach ensures repeatable quality even across different geographical regions.

Process Engineering and Training

In international installations, our training modules include focus practices, workpiece fixturing, parameter literacy and troubleshooting protocols. For details: Training and Application Consultancy.

Service and Spare Parts Ecosystem

In global projects, service success starts with the spare parts strategy. For critical components such as protective glass, scanner window, fan/filter and PSU, we offer “advanced stock” and consignment options, increasing first-visit resolution rates. Support page: Technical Service.

Standard-Compliant Safety

Operator safety begins with laser class requirements, interlocks and the condition of protective windows. Venox documents these checks in every country where installation is performed.

The Venox Value in Global ProjectsEnd-to-end solutions with a single supplier: equipment + commissioning + training + service. With transparent reporting and a planned maintenance schedule, quality and continuity are managed within the same framework.

Climate and Environmental Conditions

For humidity, dust and temperature fluctuations, extraction layout, air-knife systems and filter intervals are adjusted according to regional conditions; maintenance windows are optimized by monitoring the optical contamination curve.

Integration and Software

Template management, job-call workflows and data matrix verification are integrated with host systems (ERP/MES/SCADA). Parameter sets are versioned according to geography-specific energy and surface response characteristics.

Summary and Next Steps

The Venox International Series delivers global standardization, measurable quality and fast service support in one package. Based on your project’s target market and application requirements, let’s select the right configuration together and establish a sustainable marking quality by finalizing the commissioning and training plan.