Venox Teknoloji International Laser Marking Warranty Services

Venox Teknoloji manages warranty processes for laser marking machines commissioned in global markets through standardized checklists, an original spare-parts policy, and a regional service network. The goal is to provide permanent solutions that prevent recurring failures, transparent reporting, and geography-independent repeatable quality.

Legal Warranty and Coverage Principles

All systems are delivered with legal warranty in accordance with the regulations of the respective countries and manufacturer standards. Warranty evaluation is based on serial number, installation date, operating hours, environmental conditions (dust/temperature/humidity), and recorded fault symptoms. When manufacturing-related part or workmanship defects are detected, part repair/replacement and calibration validation are performed.

Extended Warranty (12–36 Months)

Extended warranty packages are offered for facilities with high operational risk and high line criticality. Packages may include prioritized field-visit windows, remote-diagnosis SLAs, limited replacement rights for certain components, and periodic calibration checks. This ensures predictable cost management and reduces unexpected expenses.

Warranty Workflow

Request > Preliminary Review > Remote Diagnostics > Spare-Part Reservation > On-Site Intervention > Test Markings & Reporting. Target durations for each step are defined in the contract and shared through monthly/quarterly reports.

Items Covered Under WarrantyRepair/replacement of manufacturing-related part defects and workmanship errors; on-site intervention when needed; and validation tests for field homogeneity, focus, and contrast after service completion.

Exclusions and Proper Use

Incorrect electrical grounding, unauthorized intervention, impact/transport damage, operation outside environmental limits, improper consumables, or unauthorized third-party parts are excluded from warranty coverage. Operator training and regular checklist usage ensure proper operation.

Calibration and Validation Tests

After every warranty-covered intervention, reference test grids are applied on reference material; focus distance, spot size, geometric accuracy, and contrast levels are measured. Calibration certificates of measuring equipment are provided as report attachments.

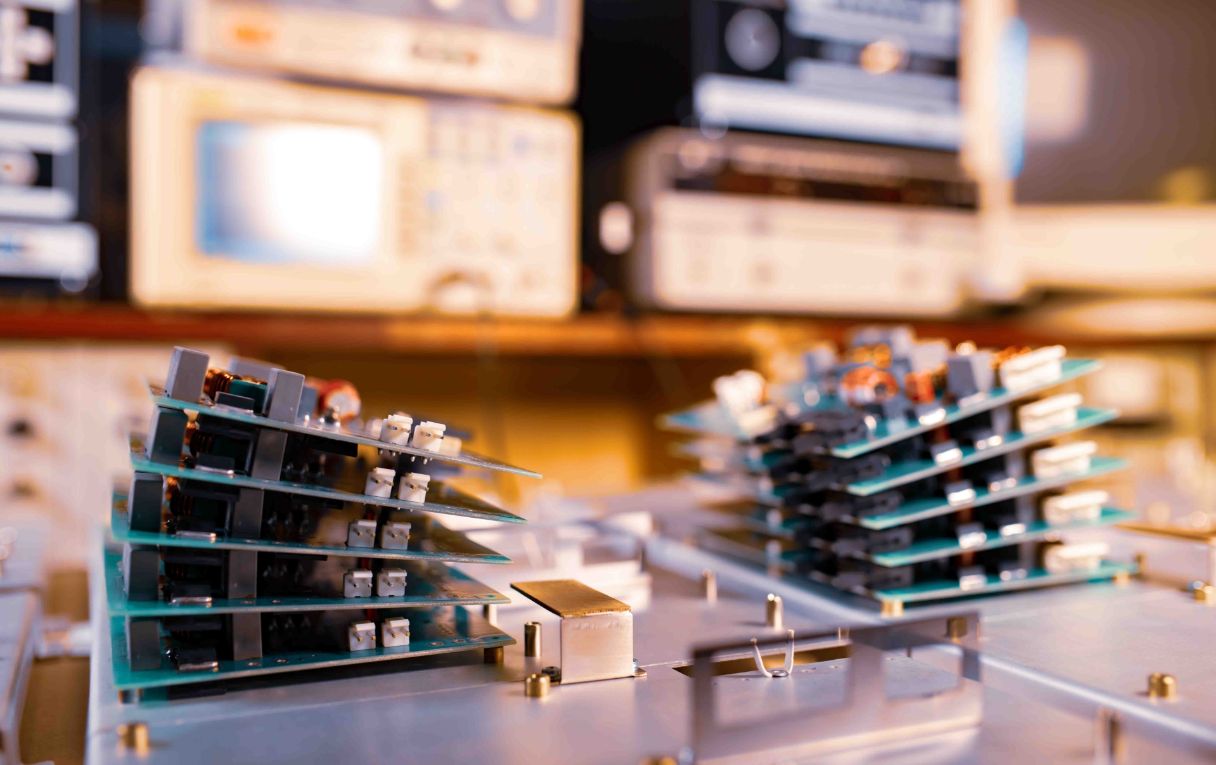

Spare-Parts Strategy and Logistics

In international projects, critical components (protective glass, scanner window, PSU, fan/filter, specific cable sets) are supported with regional advanced stock and consignment options. This increases first-visit resolution rates and minimizes customs/shipping delays.

Training and Process Support

Warranty efficiency increases with operator competency. Therefore, short training modules and process consulting are recommended during the warranty period. Related pages: Teknik Servis, Eğitim, Uygulama Danışmanlığı.

SLA and Transparent Reporting

Call response times, start of remote diagnostics, on-site arrival, and resolution targets are defined by contract. Performance metrics are shared regularly, and corrective-action plans are created for areas falling outside targets.

Summary List

- Legal + extended warranty providing geography-independent risk control.

- Original spare parts and documented repair processes.

- Remote diagnostics, fast spare-part reservation, and on-site intervention.

- Calibration/test grids for final verification.

- Sustainable quality through training and consulting integration.